Many of you would agree that supercars have never been designed with practicality in mind. Instead, manufacturers and enthusiasts have historically prioritized performance and aesthetics above comfort and fuel efficiency.

In addition to sustainability policies, economic concerns, changing consumer preferences around ownership, and other trends dramatically influencing the auto industry, some say supercars are doomed to extinction. But for many enthusiasts, high-performance cars will always have a place on our roads.

Along with the economic and social factors influencing the industry, there are also technological advances. For example, electric and self-driving cars are storming the market, and more prospective owners are purchasing their vehicles online.

Furthermore, nowadays, many buyers, even those who historically prioritized performance and didn’t mind buying supercars without a stereo, air conditioning, or power windows, now seek maximum comfort, luxury, and connectivity.

This article will explore what will happen to the auto industry and the future of performance cars.

Via World Economic Forum:

Automation, new business models, and shifting consumer trends have revolutionized many industries, and automotive is no exception. In addition, the rise of technology-driven trends continues to disrupt the automotive industry with connectivity, electrification, and autonomous driving.

However, given the widespread understanding that game-changing disruption is already happening, there still needs to be an integrated perspective on how the industry will look in the next decade or so.

Our perspective on the automotive revolution aims to analyze what changes are coming and how they will affect the automotive sector. See what others think about the future of the auto industry.

Electrification

Absolute electrification. It’s a premise that the industry is beginning to embrace in pursuit of sustainability, but it’s a major challenge. So, what strategies do the most advanced manufacturers follow?

The automotive sector, linked to the energy sector, is taking action. The reluctance to find another type of mobility has vanished with the beginning of the decade. The change is underway, and the work is accumulating for those manufacturers who didn’t want to see that the electric car was the key that opened this door.

Via Porsche Newsroom

And it’s that the urgency for electrification has evolved. In recent years we considered the viability of the electric car and how to integrate it into the manufacturing platforms. The current challenge is for electrified vehicles to conquer the entire market.

Ultra-Fast Charging Batteries

For EVs to take off, they need the ability to charge their batteries from nearly flat to complete in a matter of minutes, just like filling a car’s gas tank.

Therefore, the technology surrounding batteries is a field of research that’s accelerating at a breakneck pace. Much of it’s done in institutions and universities, focusing on developing different approaches.

For example, at Pennsylvania State University, scientists have been searching for the limits of a revolutionary battery technology for which they have recently made a breakthrough: charge times of 10 minutes and high energy density.

Via The Guardian

These prototype batteries can be charged to 70% in just 11 minutes. With minimal degradation during 2,000 charge and discharge cycles, and according to the researchers, these figures are equivalent to a useful life of 800,000 kilometers charging at high power stations. This new battery technology will reduce the cost of batteries, make them more compact and energy dense and increase their useful life in vehicles.

The technology is still in its early stages of development, so we will have to wait a few more years before we start to see it implemented in commercial vehicles. In addition, this technology encounters another obstacle: the development of the charging infrastructure that facilitates access to it.

Connectivity

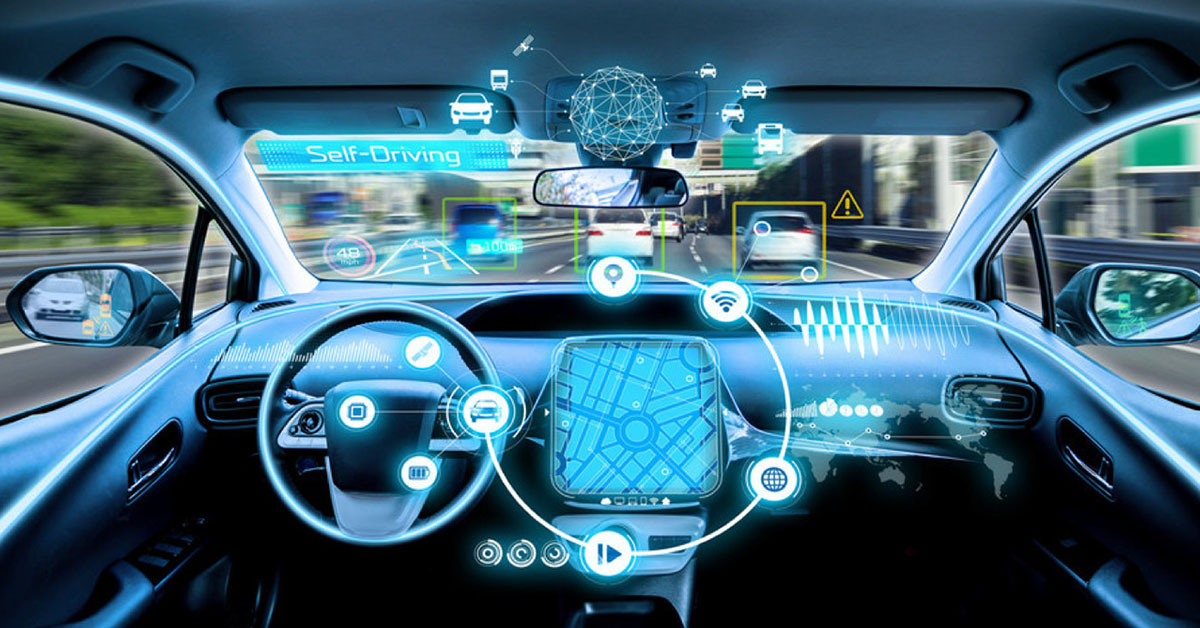

Connectivity is the information and communication technology (ICT) link between people, machines, and the Internet of Things (IoT). For example, automotive connectivity allows the vehicle to receive internet access and data from different devices.

Automotive connectivity technology allows you to control the vehicle remotely. For example, you can start the engine, unlock the car, check the fuel level, and perform other tasks from your mobile device.

Automotive connectivity will be an essential trigger for the development and rise of interconnected vehicles, where technical infrastructure and driver preferences will significantly influence. Several automotive manufacturers have already launched their first interconnected models, and expectations in the market are optimistic.

Via CRS Automotive

In fact, it is expected that by 2035 all cars sold in China, the United States, Europe, and Japan will be interconnected thanks to intelligent infrastructure, the underlying network for data processing, and the interaction between these vehicles and drivers.

Similarly, they will have connectivity called V2X (Vehicle-to-everything) that integrates a myriad of resources such as data networks, smart city systems, devices, and services, as well as everything that enriches the driving experience.

Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a significant trend in the automotive industry. Like other types of manufacturing technology, it continues to evolve and be used in many applications.

Additive manufacturing is nothing new in the automotive industry. In 2015, motor vehicles made up 16.1% of the 3D printing market, according to the Wohlers Report 2015. Initially, the applications of this technology were focused on the automobile design phase. However, car manufacturers are also 3D printing legacy parts, custom tooling, and digital inventory.

Today additive manufacturing is being used to produce entire automobiles, from utility concept cars to electric cars, sports cars, and even vehicles explicitly designed to aid scientific research.

Via 3D Print Shop

As automotive manufacturers find more uses for additive manufacturing, they also gain numerous benefits like a faster turnaround on prototypes and low-volume parts, less wasted material, lower energy usage, less need for inventory, and overall cost savings.

Autonomous Vehicles

An autonomous vehicle is a car or truck that can sense its surroundings and control its movements without human intervention. SAE, also known as the Society of Automotive Engineers, has created 6 levels of autonomous vehicles. Technically, the levels run from 0 to 5. Here is an explanation of the individual levels.

Level 0 means that there is no autonomy. With that type of vehicle, a human driver will be responsible for all driving tasks. For instance, level 1 includes driver assistance features, such as lane-keeping assist or adaptive cruise control. But the car can only do one task at a time.

Via Capgemini

Level 2 is partial automation. With this level of autonomy, the vehicle can combine 2 or more automated tasks, such as steering, and accelerate simultaneously. But even in those cases, the driver still controls the vehicle. A car with a level 5 is fully autonomous. The car can run on its own in all driving conditions. There may be no steering wheel or brake pedal in the vehicle.

Many automakers and tech giants are looking for a way to get to the front of the race, pushing to be the first to develop an autonomous car that can drive in all driving conditions.

The Future of Supercars

All of the trends we listed in this article will inevitably permeate the niche of supercars and performance cars. More and more manufacturers that have historically created their legacy in gasoline-powered supercars are increasingly betting on electrification.

For example, today’s fastest accelerating hypercar is fully electric, the Aspark Owl, which goes from 0 to 60 mph in 1.7 seconds. This results from its 1985 bhp, generated by four separate motors and a 64kWh battery, and has a theoretical top speed of 249 mph.

Another example of where supercars are heading is the collaboration between Lamborghini and Vodafone. Since 2019 Vodafone has become the worldwide connected car partner of the Italian supercar brand.

The two companies have been working together to introduce worldwide car connectivity. Nowadays, Lamborghini owners can use connected car services and gain access to Vodafone’s Internet of Things (IoT) network, accessible to Lamborghini drivers in over 190 countries.

Via Forbes

Perhaps one the most exciting examples of the future of high performance cars is the Czinger 21C. The Czinger 21C is a handcrafted hypercar created in the United States. Presented in March 2020, its production version debuted in June 2021 with a 1,267-horsepower hybrid engine that allows it to accelerate from 0 to 60 in 1.9 seconds. There’s an update that can increase its power up to 1,351 horsepower. Its production is limited to 80 units and starts at 1.7 million dollars, which in exchange is 1.60 million euros.

The new Czinger 21C is the landmark work of a company that rose to fame after building a one-off sports car from 3D-printed parts. Its name was Divergent Blade, a concept that has its successor in the 21C, which by the way owes its name to the objective with which it was born, which is to be the reference of what a hypercar should be like in the XXI century.