Supercars and hypercars, as we enthusiasts all know, are some of the highest performance, most extreme vehicles that can set four wheels to the pavement. They have more power than the average family car, they sit lower to the ground and are often shaped to take advantage of the airflow over the car to add downforce. They can be rolling works of art, or angular, angry, and ready to attack the nearest track and set a blistering lap time.

Yet, to a one, every supercar, and especially every single hypercar, are the rolling results of tens of thousands, sometimes hundreds of thousands, of man-hours in research and development. New materials and composites. New ways of building and shaping the car. New technologies to improve performance. These cars are not expensive simply for the sake of being expensive, they are expensive because they represent the best that a manufacturer can make at the time, and can even define what that manufacturer is known for. Quite often, even with their stratospheric prices, the manufacturer is taking a loss with each car sold. The perfect example of this is “The billion dollar mistake,” the Lexus LFA, that quite literally cost Toyota over $1 billion USD at the time to develop, and they sold them at about 1/3 the price needed to recoup even the manufacturing costs.

So, in the most literal sense, these supercars and hypercars are the very definition of the cutting edge of motoring, slicing through what is normal and expected to bring new ideas and innovations to the fore.

Pushing The Bleeding Edge Of Tech & Materials

Ask any true supercar enthusiast what they were doing when they first laid eyes upon the Pagani Zonda. Some saw the debut model at the 1999 Geneva Motor Show. Others saw it in a magazine, on a blog, or on a TV program that was lucky enough to get one to review. No matter what, however, everyone noticed the absolute perfection in carbon fiber that it was made of. Every single weave, where two layers of the material met, was lined up precisely to not only look good, but also provide better torsional strength and overall rigidity.

However, for Horacio Pagani, he wasn’t satisfied with just any regular carbon fiber. While Pagani Automobili produced Zondas, he tasked his materials manufacturing and consulting business, Modena Design, with coming up with a brand new material, a carbon composite that increases the strength, but not the weight, of regular carbon fiber. The result, after several years of development, was “carbotanium.” It was part of the construction material for the Zonda R, and was introduced as the primary material used to make the Huayra.

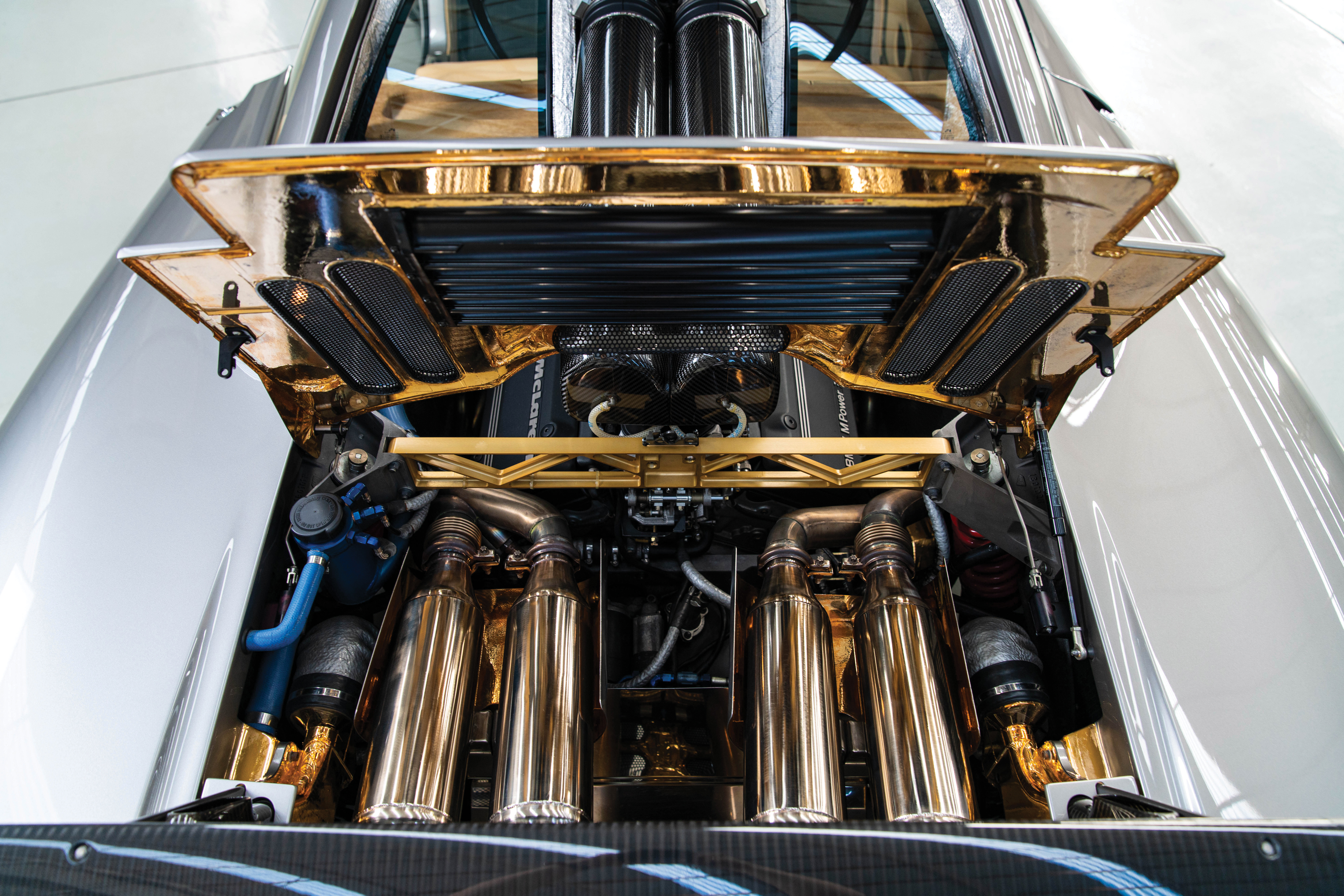

While the process to create it is long and involved, the result is a type of material that combines the highest strength-to-density ratio of any fiber, with the highest strength-to-density ratio of any known metal. Whereas normal carbon fiber starts to lose structural rigidity as temperatures increase above 150 C (302 F), carbotanium can withstand temperatures up to 315 C (599 F) all day, every day, before any structural rigidity is lost. This loss of integrity due to high heat is the core reason that the McLaren F1 had titanium engine mounts and struts, and why the engine bay was lined with gold foil as it was the best known heat reflector at the time.

It is not all about materials, however. New technologies, engines, and performance systems are also key components of supercars and hypercars, and could be argued as being more important than the materials side of things.

This is because while it may not make sense to make a family sedan out of carbotanium, a lot of the tech trickles down to “normal” cars. TPMS (Tire Pressure Monitoring System) is something you will find in almost any new car, even the cheapest econobox. 30 years ago, you would find it only on the highest end luxury cars and some high tech supercars, after Porsche introduced it with the 959 supercar. Bringing the McLaren F1 back into things, not even it, the world’s first hypercar, had TPMS integrated.

Another example is the Holy Trinity of Hypercars: The Porsche 918 Spyder, the Ferrari LaFerrari, and the McLaren P1. Each of them took the concept of a hybrid vehicle and flipped it on its head. Instead of using hybrid technology to increase fuel efficiency and extend range, they introduced the world to performance hybridization. The electric motors were used to boost power to nearly 1,000 HP, torque-fill while the semi-automatic transmissions changed gears, and even assist in braking through capturing kinetic energy to recharge the batteries.

Almost as a direct result, new performance hybrid supercars started to pepper the landscape since the last of those three cars left the factory. For example, Lamborghini brought out the mild-hybrid, super-capacitor Sian FKP, and Ferrari brought the SF90 Stradale to the road, which ironically enough has more power and accelerates faster than the hypercar that spawned it. Even now, in 2023, we’re starting to see higher end sports cars start to include performance hybrid options, such as with the Corvette E-Ray that is coming in 2024.

The Perfect Platform For New & Crazy Ideas

A manufacturer that has combined both the bleeding edge of materials and the cutting edge of tech is Koenigsegg. By definition a boutique manufacturer as they only produce between 30 to 40 cars per year, all of their models have nonetheless been nothing short of milestones. The original CC8S and CCR models were the first hypercars designed from the outset to handle E85 fuel, alongside regular petrol. The Agera was the first hypercar or supercar with a dual-clutch transmission using only one input shaft, to save weight and speed up shifts.

However, the perfect example of their craziest idea that brings everything together in a sensible way is the Gemera. A four-seat 2+2 hyper-coupe, when Koenigsegg is known for two-seat hypercars, with one of the most extreme examples of a performance hybrid system implemented anywhere. It combines a “Tiny Friendly Giant” 2.0L twin-turbo, camless inline-three engine at 590 HP, driving the front wheels, with three electric motors. One motor drives each rear wheel, and a third sits on the crankshaft, rated at 500 HP for the wheels and 400 HP for the crank, and a combined total of 1,100 HP of electric power alone.

Why this is a crazy example of a performance hybrid is that the crank mounted motor can drive the front wheels on its own, with the rear motors giving the car electrical AWD. The Gemara can run like this for about 30 miles (50 KM). Where it kicks it up a notch is when the inline-three fires up, as it doesn’t disconnect the crank hybrid, instead using it to boost the power going to the front wheels. When operating at absolute peak power, the Gemara shoves out 1,700 HP and 2,581 lbs-ft of torque.

On the materials side of the coin, the Gemera is mostly made out of a new weave of carbon fiber, as well as other carbon composites, in its monocoque chassis. It uses aluminum for subframes and the engine cradle, and has splashes of titanium throughout as well, including the bespoke Akrapovic exhaust. Inside the cabin, it is luxury hypercar heaven, with exposed carbon fiber, the finest of leathers, separate infotainment systems for the front and rear across four of the highest resolution touch screens yet fitted to a car… the list just goes on and on. A completely bonkers idea, realized in carbon and tech by Koenigsegg.

They don’t have a monopoly on crazy, however. The McMurtry Spéirling was designed, of all things, to be a middle finger to the world of hypercars. Their argument is that cars are getting heavier and heavier, including hypercars and supercars, and they set out to create the lightest-weight EV hypercar possible. It is short, squat, narrow, and has one seat. Every surface of the car is designed with aerodynamics in mind, from the quad intake nose to the way that the cockpit bubble is shaped to direct air over and under the rear wing. It carries two electric motors, each good for 500 HP, for a combined rating of 1,000 HP.

But that’s not why it’s crazy. No, that comes from the fact that it only has one seat because where the passenger would sit inline is a big-ass fan. Through a series of ports on the bottom of the car, the fan sucks up air and fires it out the rear through a pair of exhaust slats, quite literally vacuuming the car down to the road. This gives it insane downforce, and is based on the idea that Gordon Murray imagined when he designed the 1978 Brabham BT46 F1 car, which used a fan to suck the car to the road as well as cool the engine, and has repeated with his GMA T.50 supercar, the spiritual successor to the McLaren F1 he also designed.

By being small, sleek, and incredibly lightweight at under 1,000 kg (2,205 lbs), the McMurtry currently holds the record not just as the fastest accelerating EV of all time, but the fastest accelerating road-legal car. Ever. It will do 0 to 60 in 1.4 seconds, 0 to 100 MPH in 2.6, and 0 to 145 MPH in 4.98 seconds, and will shatter the quarter mile in 7. 97 seconds. This is so brain-meltingly fast that a driver is experiencing the same amount of G-force while accelerating to 60 MPH that astronauts felt during the space shuttle liftoff.

That insane performance, as well as the design principles of maximum downforce and lightest weight, shows a good idea of what could very well be coming in the next decade.

How The Cutting Edge Will Redefine The Coming EV Supercar Revolution

In the most technical sense, we’re already in the EV revolution, at least in “normal” passenger cars and some sports cars. Yes, there are electric hypercars such as the Rimac Nevara, the Lotus Evija, and the like, but there is a huge gap between high performance sports EVs and the EV hypercars. There are, as it stands, no EV supercars that are defined as such.

This is where the cutting edge, in both materials and tech, will be vital. You might have heard mention of a material called graphene, which is a layer of carbon and graphite only 1 atom thick. What is important about it is that it is a zero-gap semiconductor, which in layman’s terms means that it both conducts and stores electricity extremely well. As you may have assumed, this means that by stacking layers of graphene, you in essence create a battery, except this one will be extremely lightweight, charge much faster than any battery today, be able to handle a much wider range of temperatures, and most importantly carry a much larger charge than current batteries.

As well, new materials are being invented nearly year on year now. New technologies to manufacture and shape those materials are also coming to the fore, with a great automotive example being the Czinger 21C, a hypercar that is mostly 3D printed. Shapes that no carbon composite could be manufactured in are allowing for all-new ideas of stability, handling, rigidity, and performance to be explored.

There is an EV supercar revolution on the way, make no mistake. Porsche, Audi, Ferrari, Aston Martin… you name it, each and every one of them has a high performance, “super-EV” on the way. The only question remaining is: Who will be the first to define this all new category of supercar with the first model?