The last time we spoke, we talked about the importance of having the correct fastner for a given application. This month let’s turn our attention to keeping those fasteners in place.

TORQUE

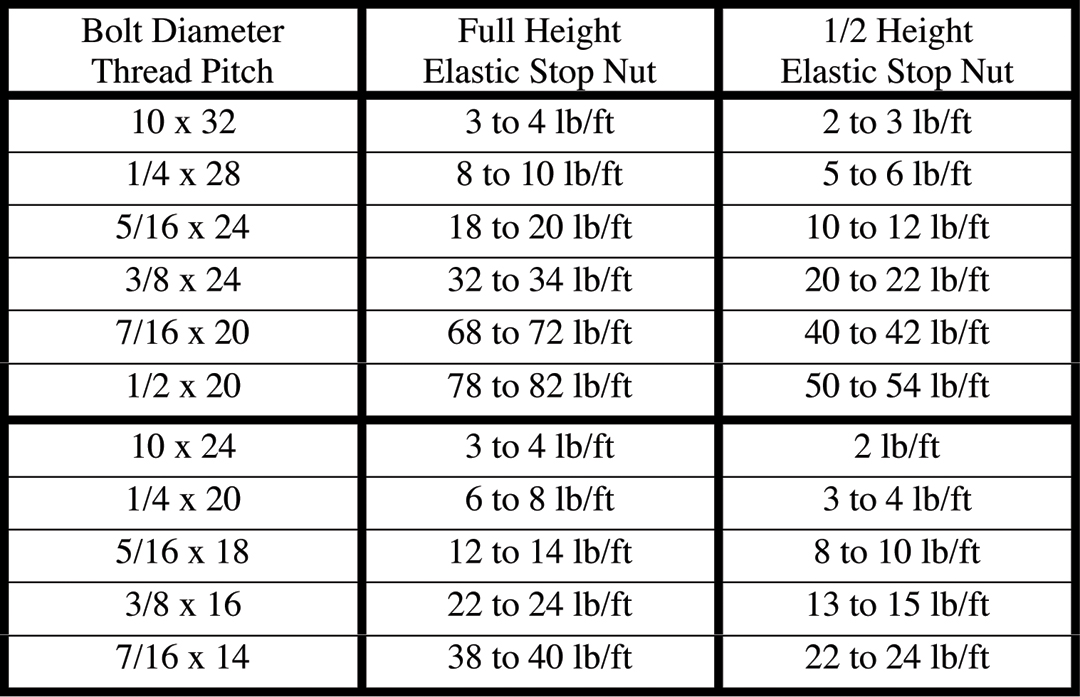

It is perfectly true that every threaded fastener should be installed to a predetermined torque with an accurate torque wrench. The proper torque is usually 90% of the yield strength of the bolt or stud. It is equally true that this is hopelessly impractical. Obviously, all engine and transmission bolts and studs must be torqued as must all critical suspension bolts in tension. For the rest, let your conscience be your guide. Remember that over-tightening is responsible for more failures than under-tightening. If in doubt use a torque wrench and the values in Figure (1). These values are for AN 3 through AN 20 airframe bolts and should be increased accordingly for Hi-Strength bolts. They are for cadmium-plated bolts with no lubricant. Consult your engine builder for critical engine fastener torque values.

SAFETY WIRE

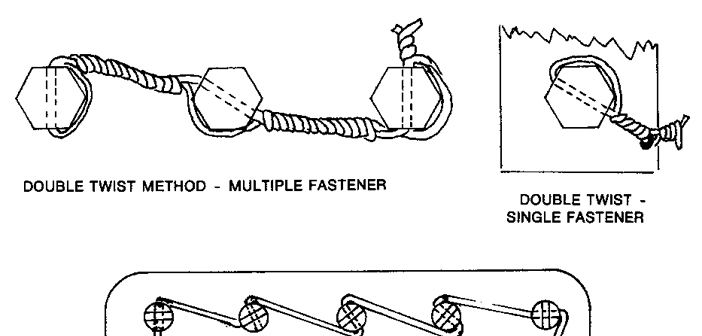

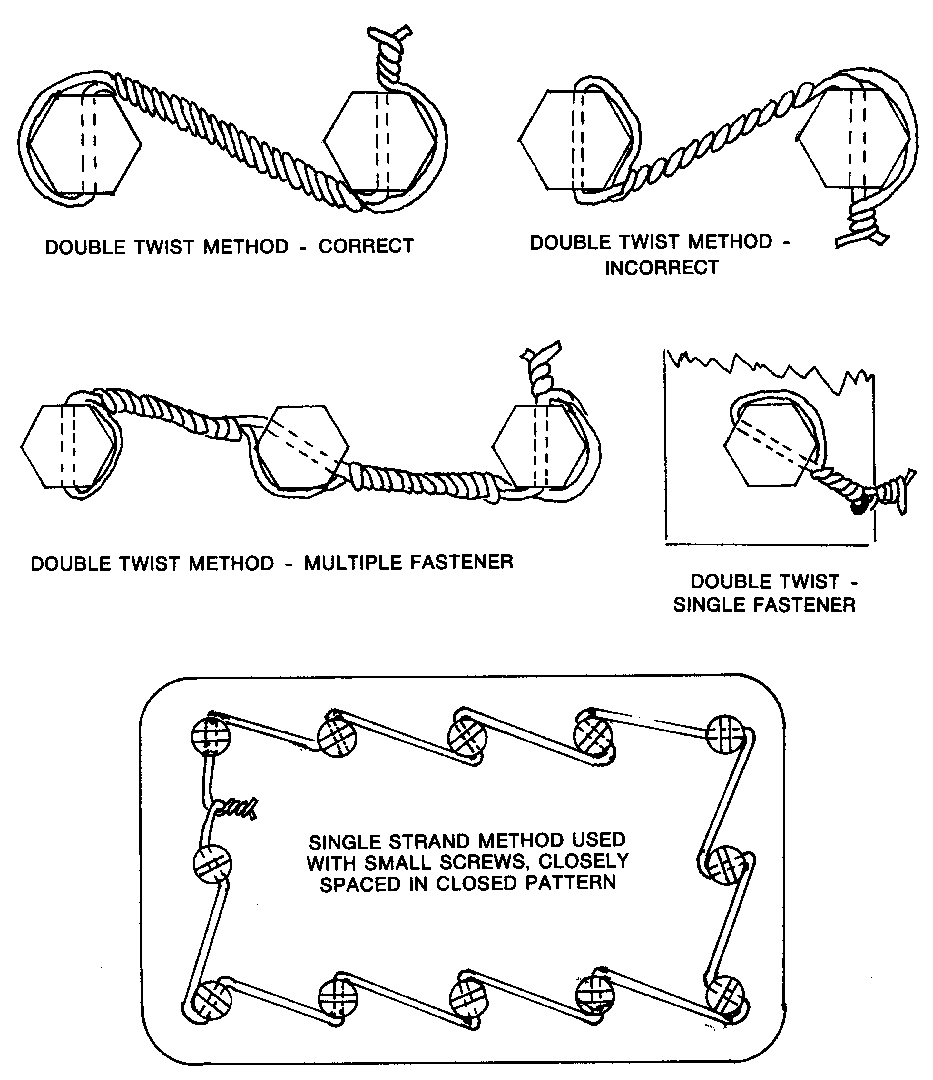

Do not trust lock washers! If it doesn’t have some sort of a self-locking nut, safety wire it. Always install safety wire so that it tends to tighten rather than to loosen the bolt. Use stainless steel wire of .032″ diameter – .020″ is handy for #10-32 screws and the like. Do not twist the wire too tightly or it will break – either now or later. Practice makes perfect. Good safety wiring is a fine outlet for one’s artistic yearnings. The best $20 you can spend is for a pair of Robinson safety wire twisters. All other brands are vastly inferior. If you cannot afford the twisters, use duckbill pliers and time. After cutting off the end of the wire, double it back on itself tightly to prevent .063″ holes in your body when next you come near the part. Figure (2) illustrates the do’s and don’ts of safety wiring.

LOC-TITE

We’ll close the threaded fastener discussion with a few words about Loc-Tite, the racer’s salvation. Loc-Tite, in its various grades, is a series of liquid self-hardening resins, which means simply that IF the right grade is PROPERLY applied to a threaded fastener, it will take the same amount of torque to undo the thing that it took to tighten it and, further, that it WILL NOT vibrate loose. This does not mean that a drop of any old kind of Loc-Tite on a dirty, oil-covered bolt will keep the bolt from coming undone. It also does not mean that Loc-Tite is a substitute for safety wire, self-locking nuts or sound engineering practice.

For our purposes, there are two grades of Loc-Tite locking resins, one sealant, two cleaners and a gap-filler. To lock a stud in place, use Stud Lock (red). To lock a bolt into a blind hole or a nonlocking nut onto a bolt use Nut Lock (blue). To seal a joint from leaking, use Hydraulic Seal. To clean any and all surfaces prior to the application of any grade of Loc-Tite, use lacquer thinner, acetone or MEK. Loc-Tite cleaner is too expensive. Do not use gasoline, which leaves an oily film. Loc-Tite applied to a dirty or oily surface achieves only one result – a false sense of confidence which can only lead to your (or at least the part’s) undoing.

My last words on Loc-Tite concern Loc-Tite Bearing Mount. Despite your best efforts and intentions, you will occasionally come across a loose bearing housing or a loose bush with no replacement available and no time or facility for remachining. Bearing Mount, used according to directions, will save the day. Carry it with you; use it when you must. But replace or remachine the offending item as soon as possible. Do not use it indiscriminately.