To think, ten years ago, 3D printing was a technology in its infancy and only available to massive organizations like NASA or militaries.

Now, you can spend anywhere from a couple of hundred to a couple of thousand dollars and have a 3D printer sit beside your computer in the office. There are even some upcoming hypercars that are mostly/entirely 3D printed.

The ones that Porsche has, however, are a bit more expensive and a lot more specialized.

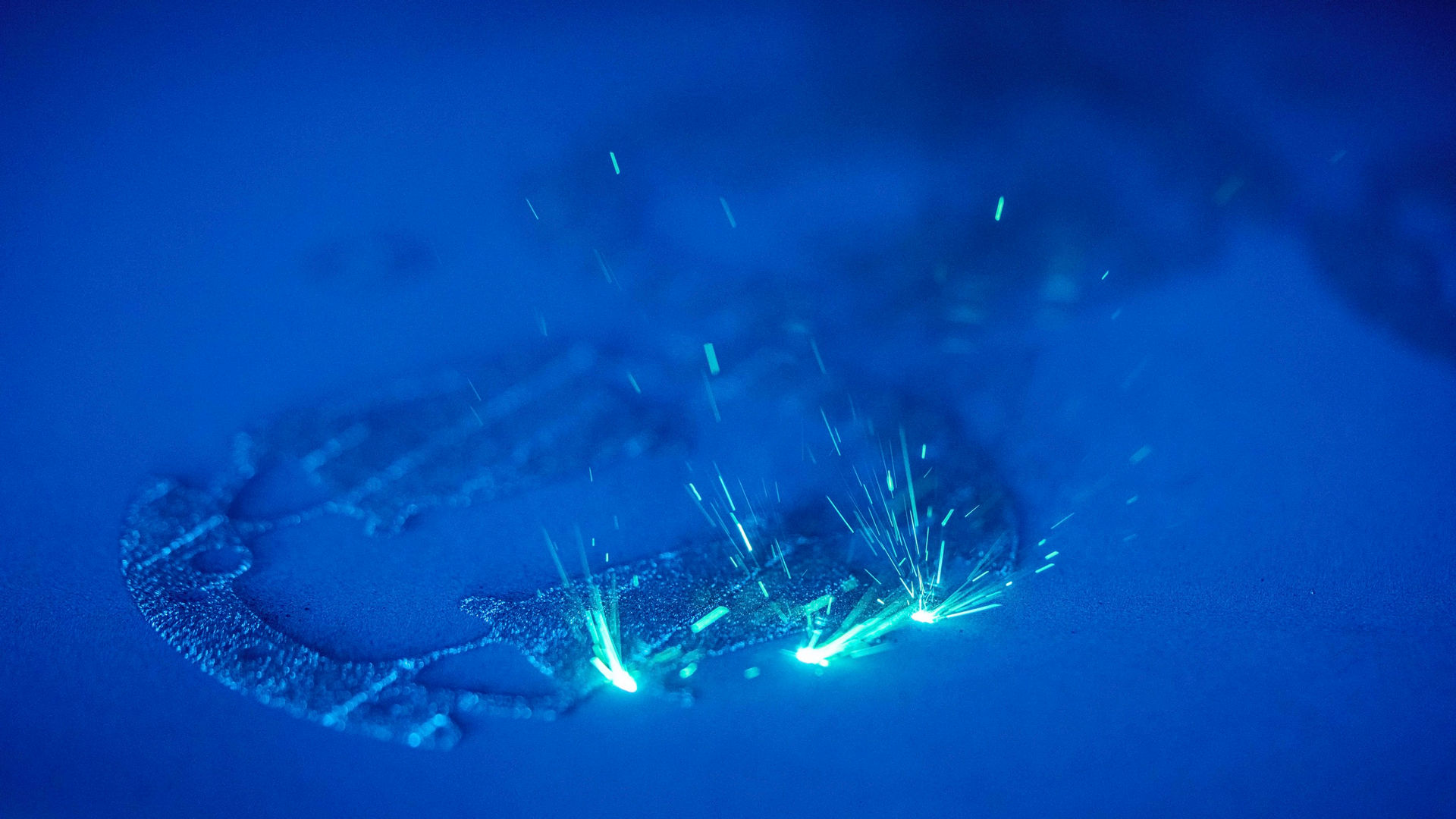

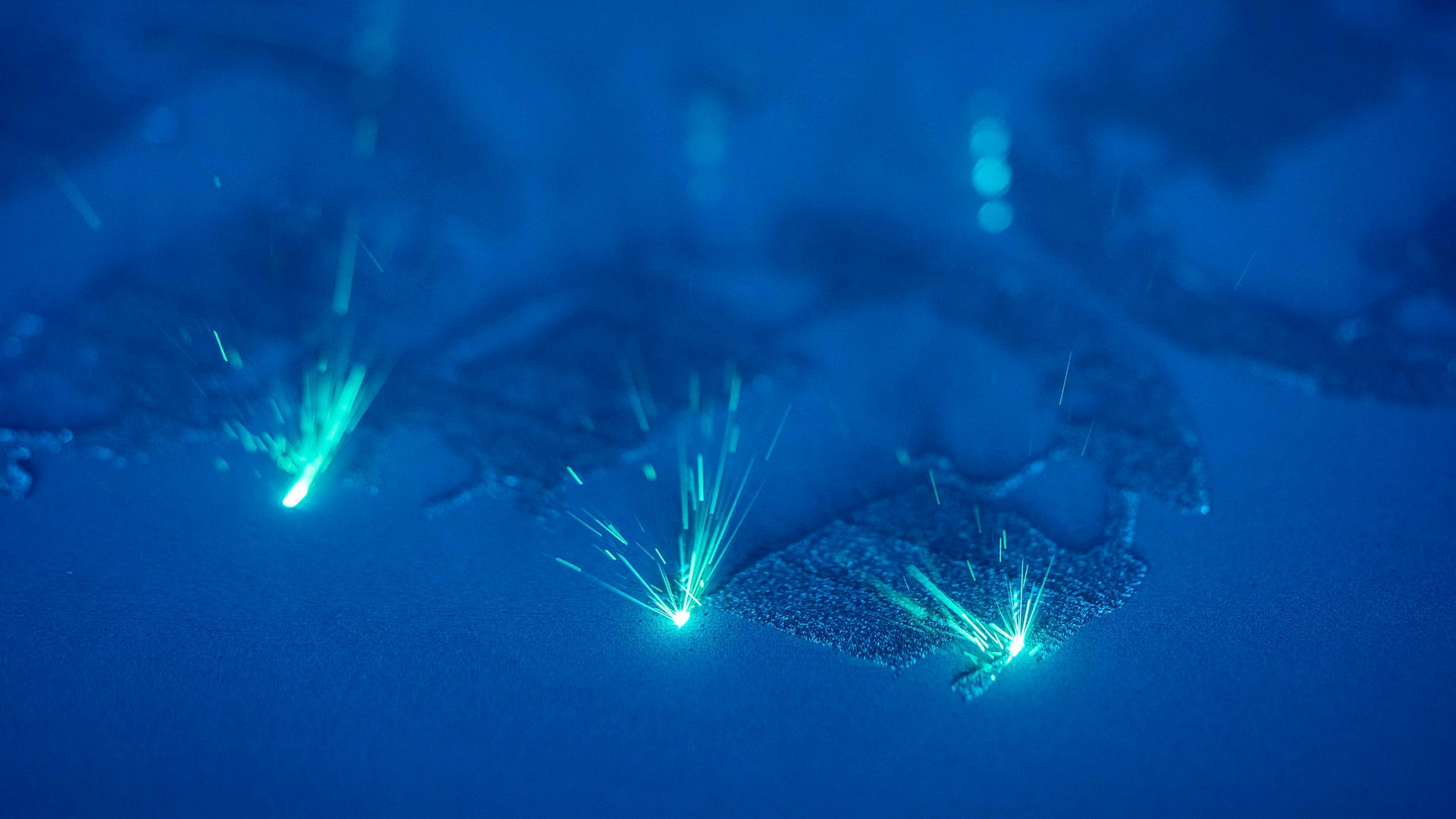

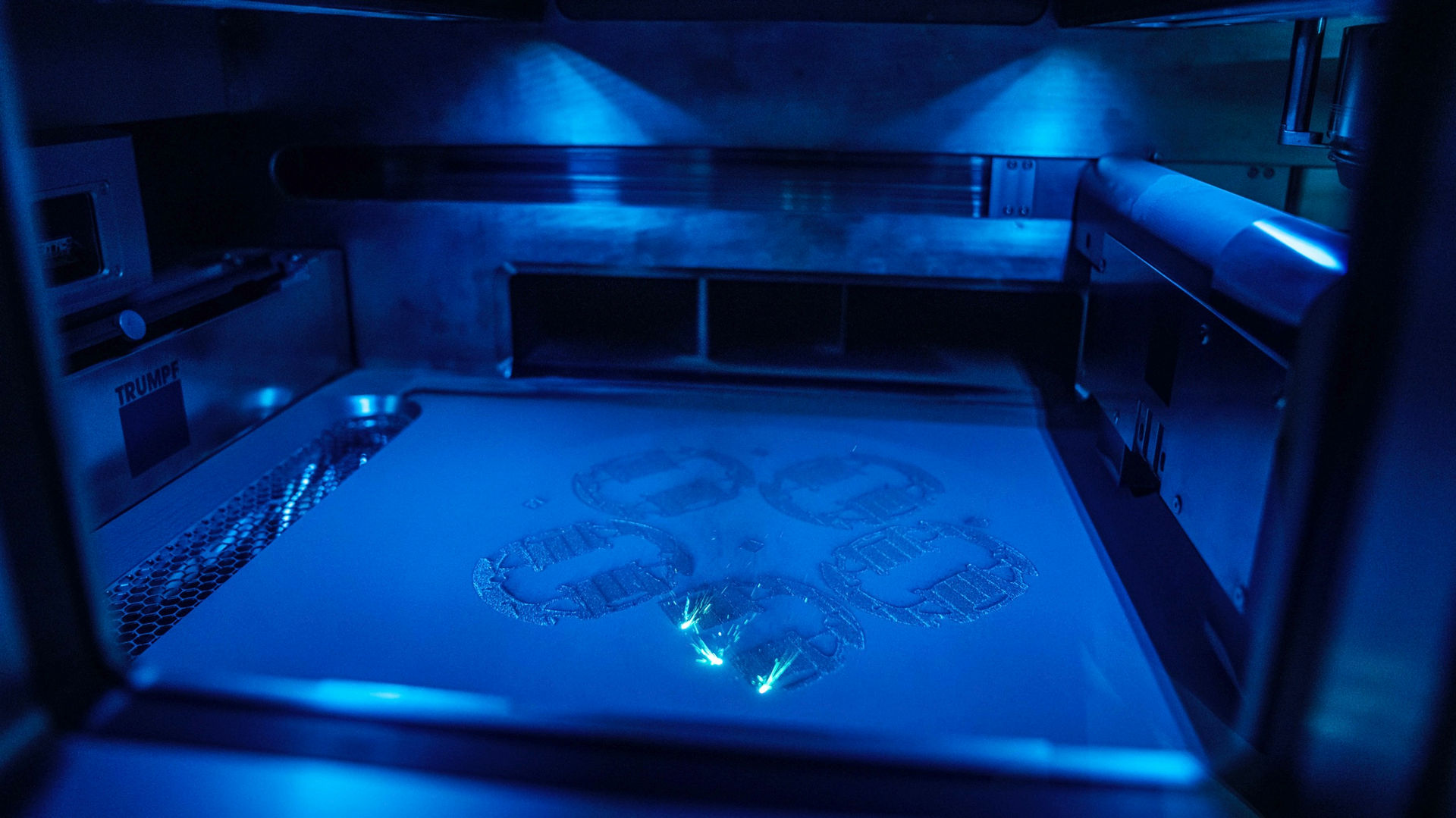

Partnered with Mahle and Trumpf (a more German name they could not have!), Porsche uses extremely pure metal powder and a laser fusion process to create extremely light and strong metal parts.

This works by the high powered lasers nearly instantly melting powder particles so that they fuse together. Through fusion, the metal atoms align much more evenly and strongly than through forging.

As well, as there is absolutely no excess metal due to the precision and power of the lasers, there is no extra weight added, and each piston can be perfectly recreated an unlimited amount of times.

This is a dream solution for a German engineer, as each piston will be at the same balance, with the same amount of metal, with the same weight. This means that the tuning for the GT2 RS engine can be more precisely programmed, to allow for faster engine speed, optimized combustion, and lower temperature load and shock across the parts.

As well, the pistons themselves are 10% lighter than the forged parts.

All of this adds up to 30 more HP over the Type 991 911 GT2 RS’ already impressive 690 HP, to 720 HP.

No news has been released yet as to when or even if Porsche GT2 RS’ with 3D printed pistons will be available for sale. However, this does mean that in the future, special models of both the Cayman and the 911 may have 3D printed pistons, among other things, to bring absolute engineering perfection to the road.