With over 60 years as a leader in innovative technologies developed in Formula 1, McLaren is advantageously placed to deliver breakthrough automotive technologies that set the standards in lightweight supercar engineering. Carbon fiber strongly represents McLaren’s innovative capabilities. Lightweight, strong, and rigid, McLaren is now approaching half a century as a world leader in this highly technical area of materials science and continues to push the boundaries of what is possible.

Carbon fiber is essential in delivering supercars with the best possible combination of attributes on road and track. Every single McLaren production car since the first, the McLaren F1, has been based on a chassis made from this composite material. The lightweight and rigidity of the material is key to delivering benchmark performance and thrilling dynamics, but also class-leading ride quality and the added benefits of efficiency. Its strength provides safety, assurance and durability. It is the perfect material upon which to create a platform for a supercar with incredible packaging solutions, enabling designers to create cars with incredible aesthetics and aerodynamic efficiency.

It is a technology firmly rooted in McLaren’s Formula 1 heritage, and is a core part of the McLaren DNA:

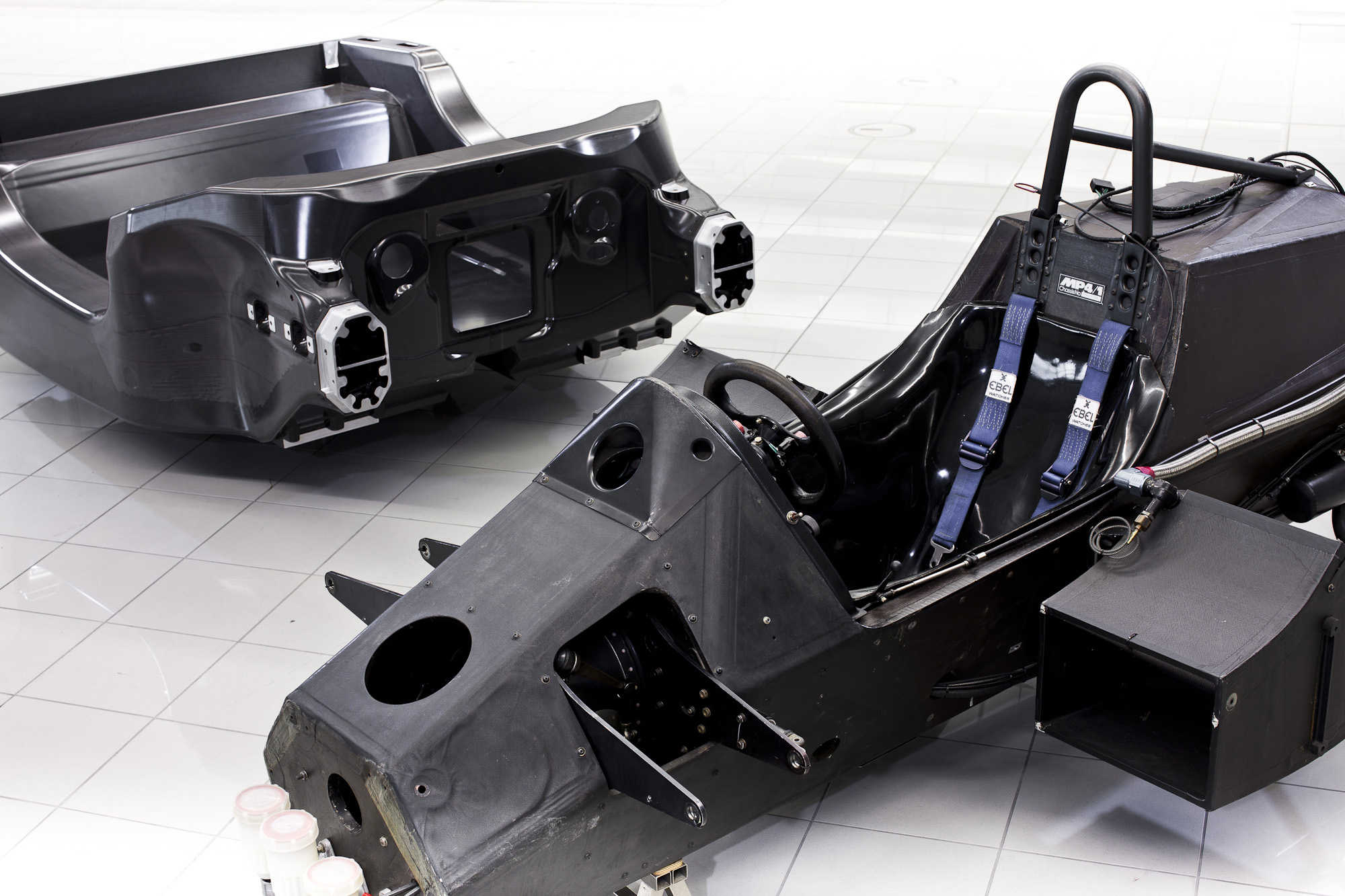

MP4/1 (1981)

The MP4/1 revolutionized Formula 1 as the first race car to use a full carbon fiber monocoque chassis. Its lightweight, rigid structure significantly improved both safety and performance. Designed by John Barnard, this pioneering chassis led to widespread carbon fiber adoption in motorsport, changing F1 car design forever.

The introduction of carbon fiber chassis cars in the sport began a modernized era in Formula 1. The superiority of carbon fiber from a safety perspective was demonstrated in spectacular fashion at the 1981 Italian Grand Prix. McLaren driver John Watson sustained and walked away from a huge 140mph accident unharmed. It was a major moment in convincing the wider Formula 1 paddock that carbon fiber chassis technology was the future of safety in Formula 1. The performance potential of a carbon chassis was made clear only three races later, as Watson won that year’s British Grand Prix by more than 40 seconds.

McLaren F1 (1993)

Of the many groundbreaking design features of the McLaren F1, utilizing a carbon fiber monocoque chassis and a full carbon fiber body, emphasizing minimal weight and maximum structural rigidity, were among the most important. Pioneering the use of carbon fiber in road cars, the F1 boasted unmatched performance because of its light weight of only 1,140kg and its immense power of 627PS from its 6.1-litre V12 engine. The carbon fiber monocoque – engineered using cutting-edge computer-aided design and analysis at the time – allowed the F1 to achieve a significant power-to-weight ratio previously unheard of in road cars, becoming an icon of supercar engineering.

It was the platform upon which not only the world’s fastest road car was built, achieving a top speed of 240.1mph at the Ehra-Lessien proving ground in Germany, but it also embarked carbon fiber technology on a complete circle of track, to road, and back again, after the F1 GTR won the 1995 Le Mans 24 Hours.

McLaren 12C (2011)

The McLaren 12C, the first road car to be produced by McLaren Automotive at the state-of-the-art McLaren Production Center, introduced the MonoCell; a single-piece carbon fiber tub that provided unprecedented stiffness and lightness in a road car at the time. The development of the chassis took the McLaren carbon fiber story into the 21st century. MonoCell was the backbone of the world’s first truly mass-produced full carbon fiber tub supercar range, delivering the benefits of this type of chassis construction on a scale never seen in the automotive industry before.

The MonoCell was one of several revolutionary new technologies introduced by 12C to the supercar segment, while also being one of the core elements in the creation of McLaren’s modern supercar DNA, laying the foundations for the future. Its advantages over the Aluminum designs still popular at the time ranged not only from incredible light weight of only 75kg for the tub itself, but tortional rigidity so great that the Spider variant of the 12C required no additional chassis strengthening – a no compromise solution true of all McLaren spiders created to date.

McLaren P1™ (2013)

Only two years on from launching the 12C, McLaren would once again revolutionize carbon fiber supercar technology with the launch of the McLaren P1™ in 2013. This second instalment in McLaren’s ‘1’ car linage took another step forward from its groundbreaking forebearer, the McLaren F1, through the use of a full carbon fiber body structure incorporating not only the roof and lower structures, roof snorkel, engine air intake cavity, but also the battery and power electronics housing that were integral to the P1’s™ high performance hybrid powertrain, in a structure known as MonoCage.

The entire structure weighed only 90kgs – a masterpiece in supercar engineering and packaging that proved to the world that electrification needn’t mean compromises on overall vehicle weight and can play an integral role in delivering performance in a true lightweight Ultimate supercar.

McLaren 720S (2017)

The 720S introduced the Monocage II carbon fiber structure that is still employed by the McLaren 750S today, further enhancing rigidity and reducing weight compared to its predecessor, the MonoCell. The lightweight structure comprises the entire passenger cell, combining a carbon fiber tub with an upper structure in carbon fiber to further enhance lightweight attributes. This significant step forward in carbon monocoque technology in series production supercars delivered not only multiple-award winning performance and dynamics, but vastly improved ergonomics, visibility and design.

The incredibly slim roof pillars of the Monocage II result in outstanding visibility through the windscreen, and combined with B-pillars that are positioned rearwards on the cab-forward cockpit, the Monocage II contributes to a sensation of exceptional space. The sills of the Monocage II drop down towards where the occupants’ feet are, for easier ingress and egress. The dramatic double-skinned dihedral doors hinge forwards and upwards as they open, taking a portion of roof in the process. The carbon cell had delivered a supercar as easy to get in and out of as easy is it was to extract maximum performance from.

And like the advantages introduced by MonoCell, the Spider version of 720S and subsequently 750S features a bespoke upper rear structure in carbon fiber, without the need for additional strengthening or reinforcement to go with it, ensuring thrilling dynamics and minimal weight increase.

The McLaren Composites Technology Center opens (2018)

The opening of the McLaren Composites Technology Center (MCTC) in Sheffield, UK, in 2018 marked a £50m investment in the first standalone McLaren production facility outside Woking. This world-class facility, formed through a partnership between McLaren Automotive, the University of Sheffield’s AMRC, and Sheffield City Council, aims to be a center of excellence in composites engineering and research and in the production of new-generation carbon fiber tubs that can directly integrate with future powertrain technologies.

The first production carbon fiber parts to be manufactured at MCTC would be for the incredible, ultra-lightweight McLaren 765LT, the car’s active rear wing, rear bumper and front floor designed, engineered and manufactured at the center.

McLaren Artura (2021)

The McLaren Artura introduced the McLaren Carbon Lightweight Architecture (MCLA), designed specifically to integrate a new generation of high-performance hybrid powertrains. Lighter and stronger than previous chassis, the MCLA supports the Artura’s hybrid V6 powertrain, while continuing to optimise and develop further the structural advantages of using a carbon fiber monocoque. Manufactured at McLaren’s first ever major facility outside of its Woking HQ, the MCLA is made at the McLaren Composites Technology Center in Sheffield. The MCLA marks a revolutionary moment in carbon fiber monocoque technology, enhancing not only the lightweight and rigidity benefits previously developed into the MonoCell and MonoCage II structures, but incorporating a safety cell for the battery of the hybrid system used by the Artura and integrating further crash and load-bearing functionality into the tub.

McLaren’s revolutionary technologies also allowed the production of the Artura’s MCLA carbon fiber monocoque in volumes never before achievable. With the launch of the Artura Spider, McLaren continues its lightweight spider DNA, with no further strengthening or reinforcement for the chassis of the Artura Spider required over its coupe variant—McLaren’s first convertible high-performance hybrid supercar delivered without compromise.

McLaren W1 (2024)

The McLaren W1 continues McLaren’s lightweight carbon fiber DNA evolution with the arrival of the Aerocell, our most radical and technologically advanced carbon fiber tub ever designed for a road car. Constructed using pre-preg carbon fiber, this technology – as used on the hyper exclusive, track-only Solus GT – uses composite that is pre-impregnated with a resin system that simplifies the curing process. Pressure treatment is then applied in the mold, which gives the Aerocell higher structural strength than comparable tubs.

Pound for pound, it results in a lighter tub that negates the need for additional bodywork in places on the car’s exterior – a lightweight benefit explored in the design of the W1. The Aerocell has also been designed as a key element of the W1’s extreme aerodynamic package making use of true ground effect, achieved by raising the floor of the monocoque by 65mm, which has lifted the footwell position and rising to 80mm towards the front of the Aerocell. At the same time, to reduce the length of the Aerocell – and of the overall vehicle – the decision was taken to fix the seat position and incorporate seating into the monocoque. Reducing the wheelbase by almost 70mm, this also has the added benefit of saving further weight.

The McLaren W1 also sees the introduction of McLaren’s next-generation carbon fiber technology; McLaren ART carbon fiber. Made possible via the development of McLaren’s breakthrough Automated Rapid Tape (ART) ‘high rate’ deposition manufacturing technique, McLaren ART carbon fiber unlocks new possibilities for engineers. Lighter and stiffer, produced with fewer waste materials, and enabling the rapid creation of optimized carbon fiber parts with specialized properties, the active front wing of the McLaren W1 debuts this new technology.

“Carbon fiber is integral to the McLaren story and a core part of our DNA. It enables us to deliver super-lightweight supercars with the very best dynamic attributes and it remains an area of technical exploration with much to discover, and many more gains to be realized.”

Michael Leiters, Chief Executive Officer, McLaren Automotive

Above content © 2025 McLaren Automotive, reviewed and edited by Rex McAfee