Gasket Works

So what do you do if you’re a leading pulmonologist, at a National Cancer Research hospital, and you can’t find a decent head gasket for your vintage racecar? Well, you make your own.

As surprising as that may sound, that was exactly the situation that Dr. Mordy Dunst found himself in, back in 1992. With the help and expert advice of his father-in-law, former Le Mans racer Mike Rothschild, who also happened to own a copper smelting business, Dunst began experimenting with the creation of custom solid copper head gaskets.

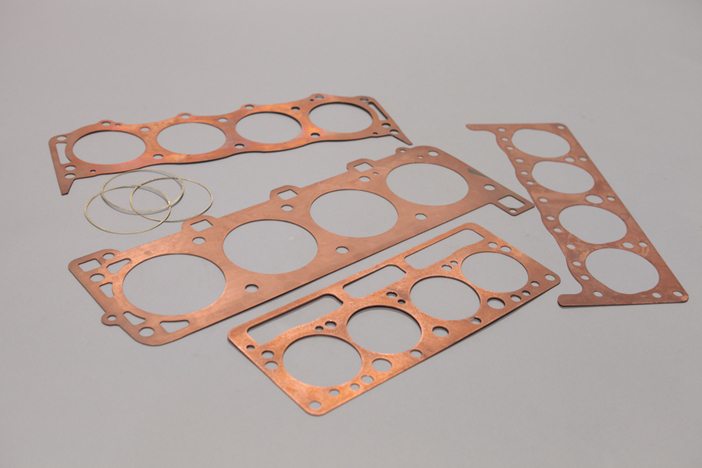

With experimentation and experience garnered on the track, Dunst not only developed a reputation for his custom head gaskets, but also began to be approached by others who needed help with special applications or unique installations. With increased requests for custom applications, Dunst invested in a computer-controlled high-pressure abrasive waterjet cutting system that would enable him to digitize and reproduce any gasket accurately and reliably, as well as modify or improve it. Soon Dunst was making custom head gaskets for Alfas, Ferraris and Porsches, as well as rarities like Alvis, Duesenberg, Delahaye, Daimler, Stanguelini, Wollsely and many others. Interestingly, he has also had the opportunity of making custom gaskets for spark ignition, compression ignition and hydraulic motors for laboratories such as Sandia, Lawrence Livermore, JPL and DARPA.

Not only does Gasket Works now offer literally hundreds of domestic and import gaskets, but they can also produce these in a wide variety of thicknesses (standard thicknesses include: .022, .032, .040, .043, .054, .063, .070, .086, .093, and .125-inches). Whether an owner wants to raise or lower compression, or compensate for a head or block that has been damaged or flycut, Gasket Works can provide a custom application that achieves results that standard OEM or aftermarket gaskets cannot.

Additionally, for the past five years, Gasket Works has been making custom compression “rings” from .005″ stainless steel to improve the axial clamping forces near the combustion chamber perimeter. These rings can be made precisely to surround any unique gasket bore configuration. They are typically about .080-inch in width with an internal dimension just larger than the bore. They clamp into place by their unique design—an ideal solution for race engines or high compression applications—and render obsolete the use of sloppy imbedded copper wire to surround the cylinder.

CONTACT INFO::

- Gasket Works USA, LLC

- 626.358.1616

- www.Headgasket.com

- [email protected]