The Carmen Sagrera is powered by four electric motors delivering 1,114 hp and accelerates from 0 to 100 km/h in just 2.6 seconds, providing the thrilling driving experience a true gentleman driver seeks. This exclusive model is handcrafted at the company’s Barcelona headquarters and involves a painstaking process that combines innovation, design, and craftsmanship. These are the five fundamental steps in its creation, incorporating recent evolutions that make this car a true work of art on wheels.

Phase 1: Pre-assembly of components and battery production

Production of the Hispano Suiza Carmen Sagrera begins in parallel with the customer’s vehicle configuration. As this is a highly customizable model, making each unit unique in line with the brand’s “hyper lux ” concept, the company’s design team is in regular contact with the future owner to adapt the car to their tastes and inform them of the progress of production.

The first steps involve pre-assembling various items, such as the front and rear subframes, the suspension system, the axle shafts, and the interior dashboard. The steering is installed on the front subframe, and the rear subframe is fitted with support for the inverters and the propulsion system (motors and gearbox, which have been previously tested and calibrated on the dynamometer).

At the same time, the company’s technical team started building the 103-kWh battery pack, manufactured in-house, which made its debut on the Hispano Suiza Carmen Sagrera last year. Thanks to it, this model has a driving range of up to 480 km. At the same time, another team starts producing the high-voltage wiring.

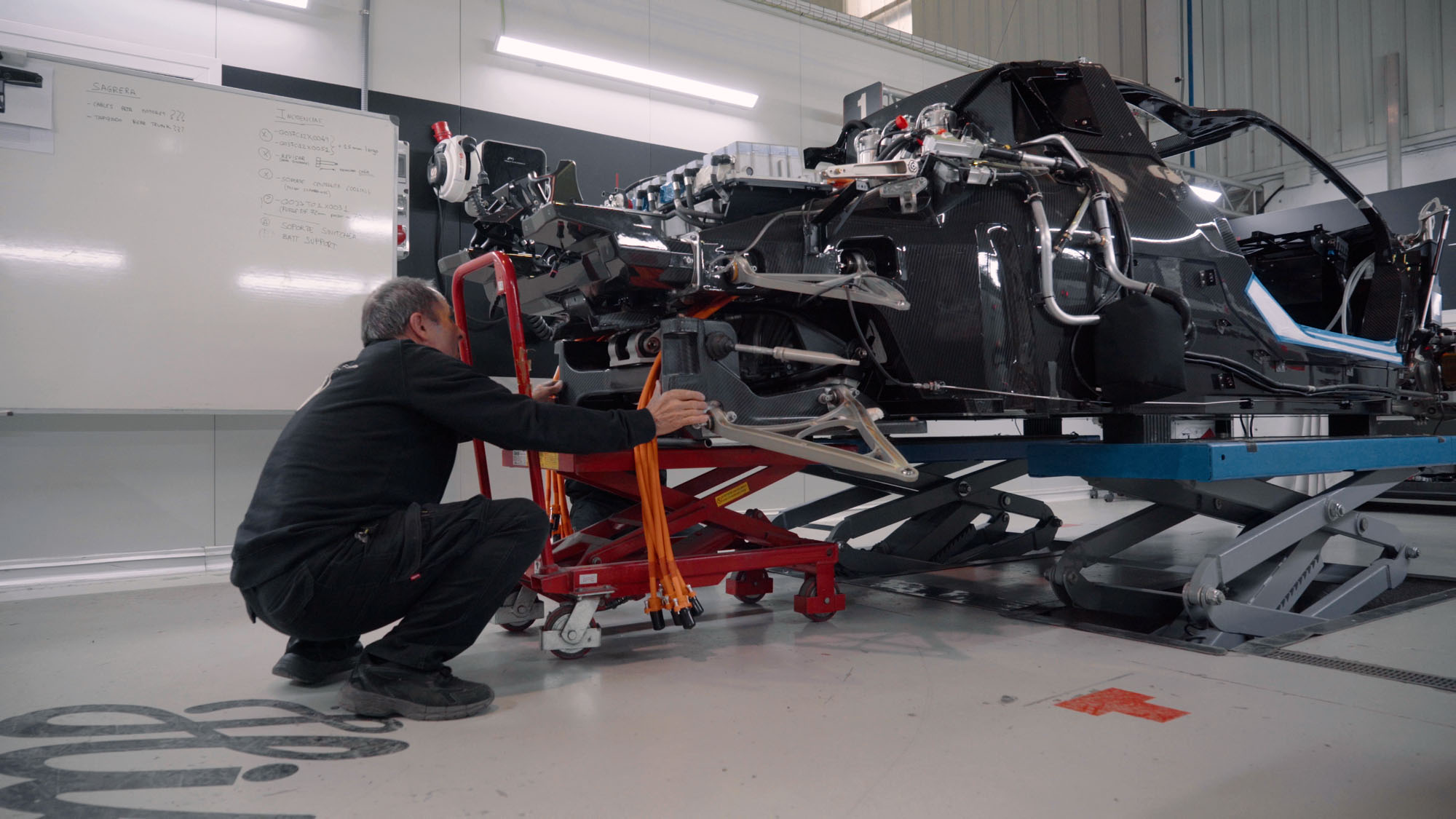

Phase 2: Assembly of the chassis

The production of Hispano Suiza’s latest hypercar continues with the installation of different body elements on the carbon-fiber monocoque. This process is carried out by hand, with great attention to detail, so each piece fits perfectly. Some interior elements are also installed.

Phase 3: Painting, upholstery, and rolling chassis assembly

After the pre-fitting and adjustment of all the parts, the painting process begins with the color specification selected by the customer from among the virtually infinite possibilities offered by the brand. Hispano Suiza technicians also carry out this work by hand, highlighting the company’s care and attention to detail. The final treatment of the body parts is also carried out.

The wiring, cooling system, steering, and brackets are installed, while the front and rear subframe and all the rolling chassis components—suspension, brakes, and wheels—are also assembled.

In parallel, the interior upholstery, featuring high-quality materials such as Alcantara or leather, is cut and sewn by hand according to the owner’s selection.

Phase 4: final assembly and infotainment

The production process of the Hispano Suiza Carmen is drawing to a close. With the chassis already assembled and ready to roll, the technical team is focusing on the final assembly and adjustment of the interiors, which includes installing the infotainment and all the comfort systems it contains. The final assembly of the exterior is also carried out, including the emblems and logos with the stork as the main protagonist.

Phase 5: Final validation and handover

Once it has been built, the Hispano Suiza Carmen Sagrera is ready for delivery to the client. Around eight months will have passed since the start of the process. The last phase consists of validating the assembly during a test drive on the road and track at the Circuit de Barcelona-Catalunya (Montmeló), located next to the brand’s facilities. Once it has been thoroughly checked that the vehicle is in perfect condition and that all the systems are working correctly, it will be handed over to its new user, who can enjoy a supreme driving experience.

Above content © 2025 Hispano Suiza Cars-Peralada Group, reviewed and edited by Rex McAfee