2009 Audi R8 LMS

For the first time, Audi Sport will offer a racing sports car specifically developed for customer use in the form of the powerful 500 hp plus GT3 version of the Audi R8 which will be available from autumn 2009. The logistics and factory space required for the AUDI AG customer programme will be created over the next few months in Ingolstadt, Neckarsulm and Gyr.

“The R8 is the first production Audi bearing the name and genes of a successful racing sportscar and is therefore an excellent base from which to build up our first big customer sport programme, explains Head of Audi Motorsport Dr Wolfgang Ullrich. “Ever since the R8 was unveiled weve been inundated with enquiries about a race version. With the Audi R8 we will offer customers a racing sportscar equipped with high-calibre technology and the typical Audi qualities, but which is nevertheless easy to handle.

The Audi R8 conforms to the production-based GT3 regulations allowing the car to be fielded in numerous national and international race series. Audi respects the spirit of the class – to offer production based, low-cost but powerful racing cars – in all aspects of the vehicle conception.

Because the GT3 regulations prohibit the use of four-wheel drive the Audi R8 comes with the typical GT rear-wheel drive. The power is transmitted via a newly developed six-speed sequential sports gearbox. The suspension uses almost exclusively components from the production line. A comprehensive list of safety equipment guarantees the highest-level of passive safety. A modified front end and a large rear-wing generate the required downforce for the race track.

The development has been carried out since January 2008 in close cooperation with Abt Sportsline, the team with which Audi has won the DTM title three times since 2004 with factory programmes.Mid August, the first prototype successfully completed a roll-out in the hands of Audi factory driver Frank Biela.

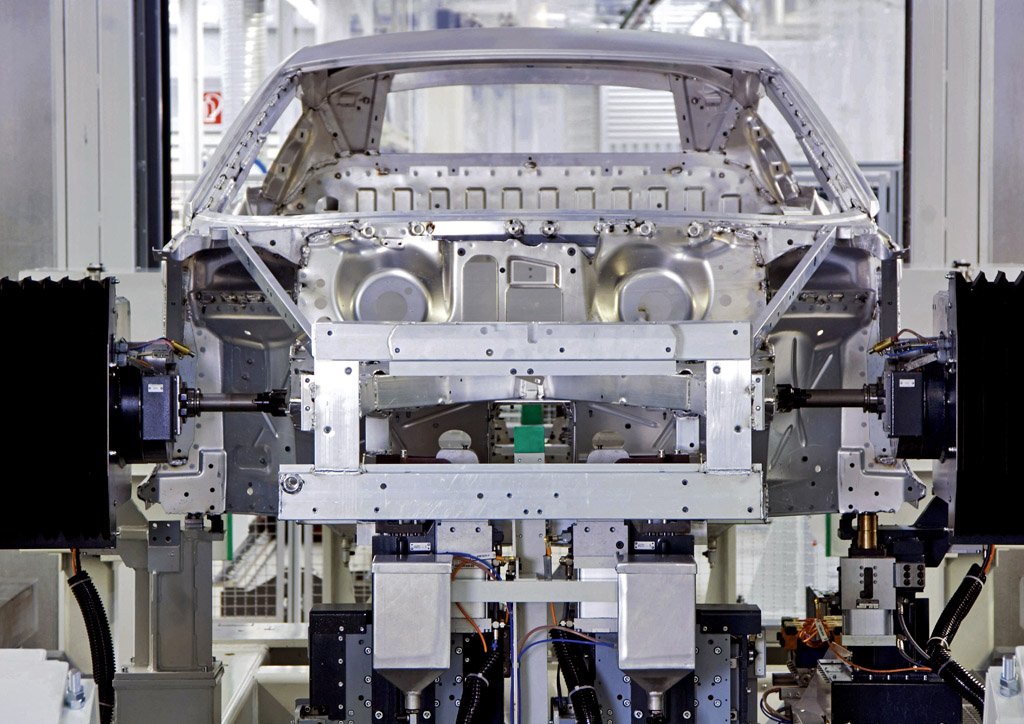

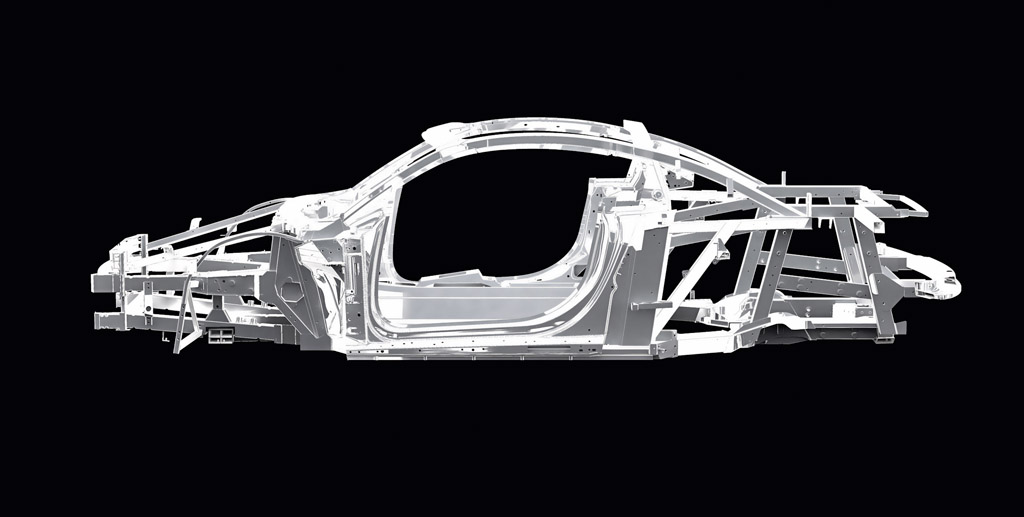

The road going sportscar based on the lightweight aluminium Audi Space Frame (ASF) with its conceptual roots in racing provides the perfect basis for motorsport. Whether chassis structure, engine position, suspension or brakes – many elements could be carried over entirely from the production line or with small modifications. quattro GmbH takes a standard production chassis from the production line in Neckarsulm as base for every R8 LMS. After the roll-cage is fitted the R8 LMS is completed at the quattro GmbH. The Audi Hungaria Kft. production line in Györ provides the 500 hp plus V10 engine. Audi Sport in Ingolstadt assumes absolute responsibility for project development.

Many active safety elements

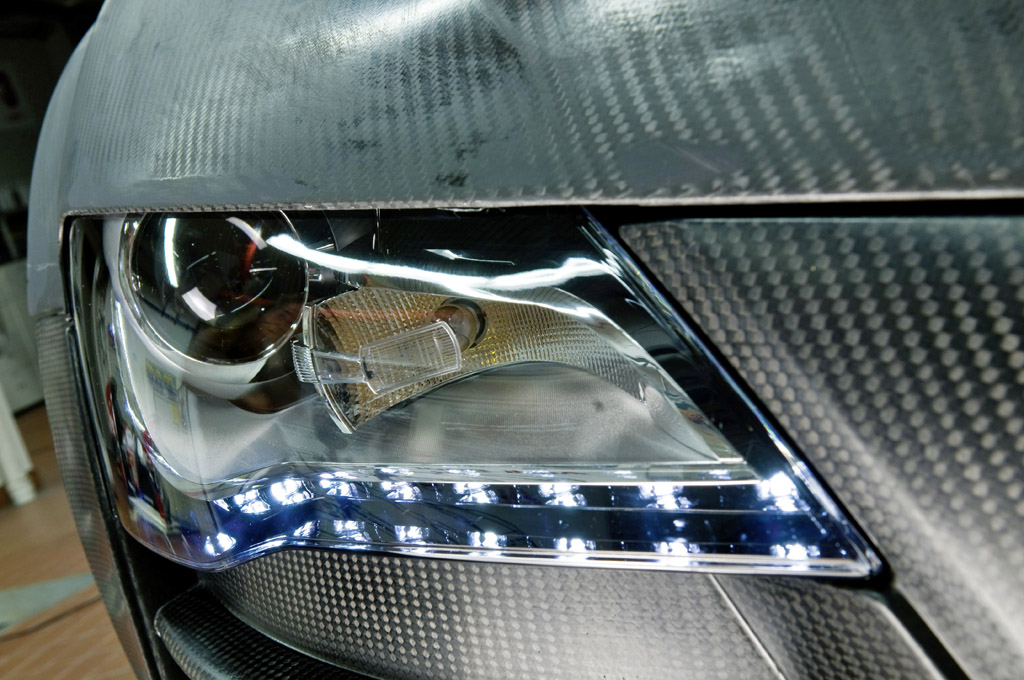

Like every Audi the Audi R8 LMS also guarantees first-class safety. The sportscar designed for customer sport offers exceptional active safety. The range starts with the most prominent external features, the standard lighting system with

Xenon plus headlights and LED tail lights. A race ABS, the minutely adjustable traction control (ASR) and the specially tuned suspension take every demand into consideration.

“The car is extremely well balanced,” stresses Frank Biela who has won the 24 Hours of Le Mans five times with Audi since 2000. He shares the set-up work with Nordschleife expert Frank Stippler and Christian Abt, the German Super Touring Car Champion in 1999. “The R8 LMS can be driven easily on the limit in a drift and won’t spring any nasty surprises on the GT3 customer. The ABS is ideal to prevent the driver from sliding off and flat spotting tyres.”

The steering and seat are further active safety elements. The steering column length and angle can be adjusted, and the Recaro bucket seat moves longitudinally to allow drivers of different statures sharing a car to sit perfectly. During a race, drivers must never remove their hands from the steering wheel since the production six-speed

gearbox adapted for racing purposes is activated by shift paddles. For this purpose Audi successfully transferred technology from professional racing: The pneumatic system required for such gear-shift procedures originated from the R10 TDI race car. Finally, the complex rapid refuelling system from Stäubli ensures splash-free fuelling and helps to prevent possible burn injuries. The standard production allwheel drive quattro – another active safety feature – is however unfortunately prohibited by the regulations.

The passive safety elements of the R8 LMS are also exemplary. Starting with the strength of the aluminium frame ASF via the standard door design with high safety reserves in the event of a side impact to the motorsport specific additional

equipment: The Audi R8 LMS exceeds the demands of the regulations by far. The steel roll-cage is manufactured from tube with greater wall-thickness than specified in the regulations. The R8 LMS is also fitted with a new motorsport 120 litre tank located in an optimum position behind the cockpit. The extremely complex fire-extinguisher system completes the excellent occupant protection.

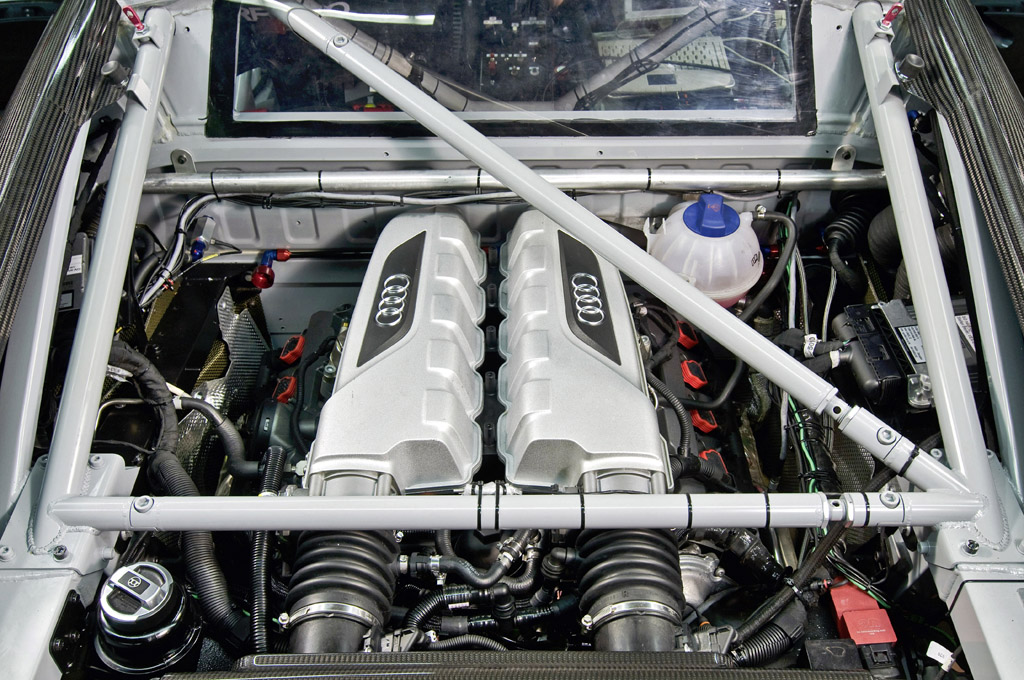

Engine

The R8 LMS is powered by a 500 hp plus V10 engine. Derived from a production unit, the race engine is ideally suited for racing purposes. The normally aspirated unit is mounted longitudinally in front of the rear axle of the Audi R8 LMS.

Audi Sport tests showed that the production dry sump lubrication is more than a match for all racing conditions. The system reliably fed oil to all the necessary points in the engine even when subject to high centrifugal forces. There are significant differences between the

basic production engine’s peripheral devices and its racing counterpart where the devices are omitted. The engine is built at the Audi factory in Györ, Hungary.

HIn addition to other modifications Audi fundamentally re-worked the exhaust system for motorsport use. The lightened exhaust manifolds on the right and left cylinder banks are each fitted with race catalytic converter. As a result, Audi exceeds the requirements of the GT3 regulations which do not specify use of emission control. However, with more than 500 hp and over 500 Nm torque the power plant will number among the more powerful engines in the GT3 sportscar field.

Chassis

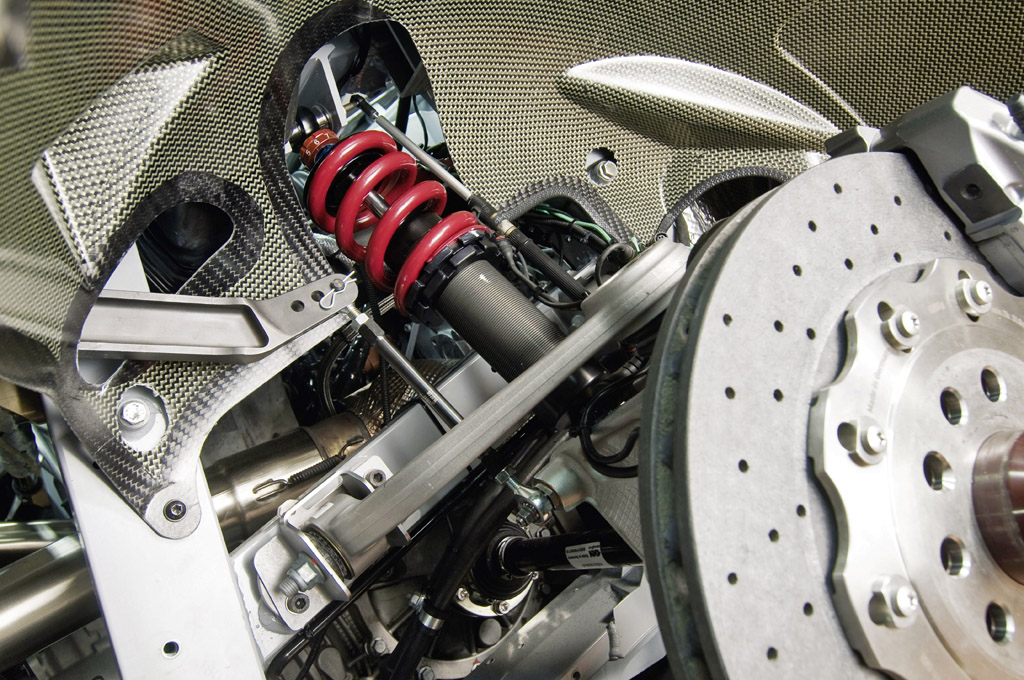

The Audi R8 has an Audi Space Frame (ASF) as standard. The pioneering aluminium frame to which double-wishbone suspension is mounted at the front and rear also forms an ideal base for motorsport and helps the R8 LMS to achieve a total weight of 1,250 kilograms. The chassis is removed from the quattro GmbH production assembly line in Neckarsulm before undergoing small modifications for motorsport.

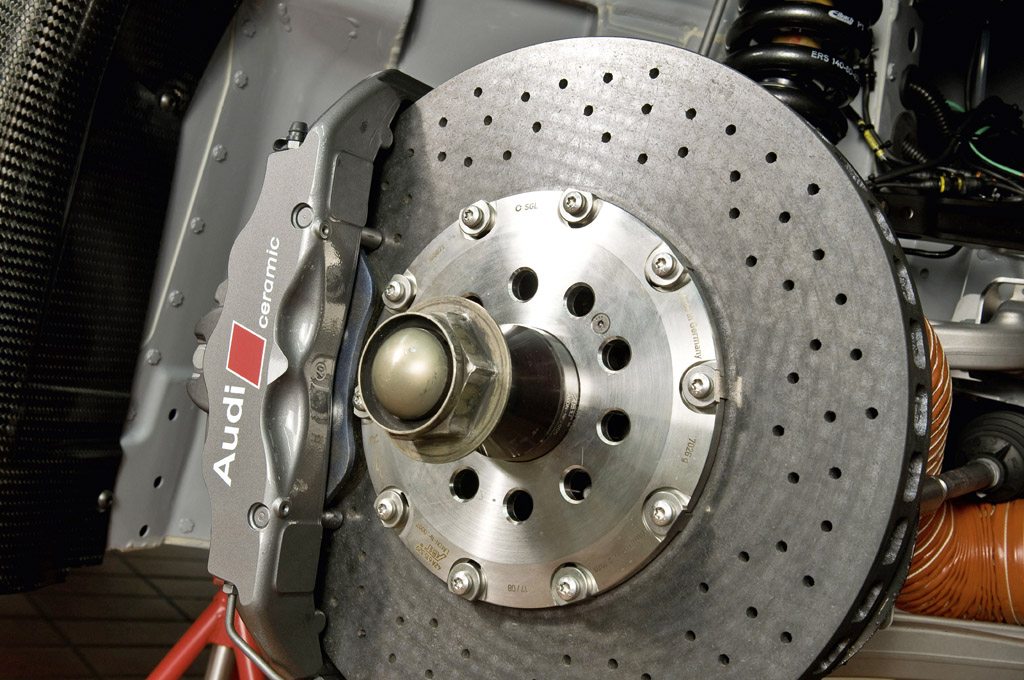

In spite of the considerable performance potential of the R8 LMS many production functions also prove themselves in motorsport. For instance, the ceramic brakes, available ex-works, which only have new brake pads for racing are carried over.

The double wishbone suspension parts produced almost completely from forged aluminium are retained as production parts or differently

machined production blanks. The lower front and upper rear wishbones are attached to higher mounting points in order to reduce the ride-height. In the same way, Audi adapted the steering position. The six-speed gearbox, which uses a twin-plate clutch, is also production based, while the quattro four-wheel drive is prohibited by the regulations. A gear-dog ratio set from Australian supplier

Holinger replaces the standard production, fully-synchronised gear ratio set in the paddle-controlled, pneumatically activated gearbox.

The roll-cage must be made, as specified by the regulations, of steel and is therefore bolted to the aluminium chassis. The three pneumatically operated air jacks to lift the car are also new. The anti-roll bars fitted are genuine racing parts. The Eibach coil springs and the Bilstein dampers adjustable in bump and rebound were also developed for motorsport. The hubs used on the R8 LMS also differ from the production part and have a centre-lock wheel nut. Audi also adapted a race ABS brake system and the traction control ASR for perfect handling and control.

Bodywork and aerodynamics

The production car’s fascinating bodywork form is styled by the same design team as the outer skin of the R8 sports prototype that won the 24 Hours of Le Mans five times between 2000 and 2005.

Apart from its enormous rear wing the R8 LMS is almost identical to the R8 at first glance. However, the squat appearance of the race car can be put down to many factors. To achieve a lower centre of gravity the R8 LMS, at a height of 1.19 metre, crouches low above the road – another 5.4 centimetres lower than the low production sportscar. To accommodate the voluminous 18 inch Michelin race tyres (270 millimetres wide at the front, 310 millimetres on the rear axle) the bodywork width grew from 1.90 to 1.98 metres. The overall length also increased with the addition of the front splitter and rear wing – by four centimetres to 4.47 metres. Since modifying the production aluminium components or pressing new metal bodywork panels would generate far greater costs Audi Sport decided to manufacture almost the entire outer skin from carbon-fibre composite (CFC). Only the doors, which fulfil the most stringent safety standards, remain completely as production parts. The aluminium roof panel also originates from the production line. To maintain the look-and-feel of the production car the original body panel split lines were retained.

2009 Season

The first test races in various European racing series are scheduled for the 2009 season. The fully homologated Audi R8 LMS is available to customers from the 2009 season for a target price of 262,000 Euros plus VAT.

The customer cars are manufactured together by Audi Sport and the quattro GmbH, which is also responsible for production of the Audi R8 street version, and Audi Hungaria Motor Kft. (Gyr).

Story by Audi Sport

In Detail

| type | Racing Car |

| released at | 2008 Essen Motorshow |

| built at | Neckarsulm, Germany |

| price $ | $ €262,000 |

| engine | 90 Degree V10 w/Dry Sump Lubrication |

| position | Front Longitudinal |

| aspiration | Natural |

| block material | Aluminum Alloy |

| valvetrain | DOHC, 4 Valves per Cyl w/VVT |

| fuel feed | FSI Direct Injection |

| displacement | 5200 cc / 317.32 in³ |

| power | 372.9 kw / 500 bhp |

| specific output | 96.15 bhp per litre |

| bhp/weight | 400.0 bhp per tonne |

| torque | 500 nm / 368.8 ft lbs |

| body / frame | Cabon Fiber, Magnesium & Aluminum Body over Aluminum Spaceframe |

| driven wheels | RWD w/ASR |

| wheel type | Center-lock O.Z. Cast Magnesium |

| front tires | 27/65-18 Michelin Radial, |

| rear tires | 31/71-18 Michelin Radial, |

| front brakes | Ceramic Discs w/ABS |

| rear brakes | Ceramic Discs w/ABS |

| f suspension | Double Wishbones w/Eibach Coil Springs, Bilstein Adj Dampers, Anti-Roll Bar |

| r suspension | Double Wishbones w/Eibach Coil Springs, Bilstein Adj Dampers, Anti-Roll Bar |

| curb weight | 1250 kg / 2756 lbs |

| length | 4470 mm / 176.0 in |

| width | 1984 mm / 78.1 in |

| height | 1195 mm / 47.0 in |

| transmission | Sequential 6-Speed w/Holinger Gear Set |

| tran clutch | Sinter metal twin-plate clutch |

| fuel capacity | 120 litres or 31.68 gal. |