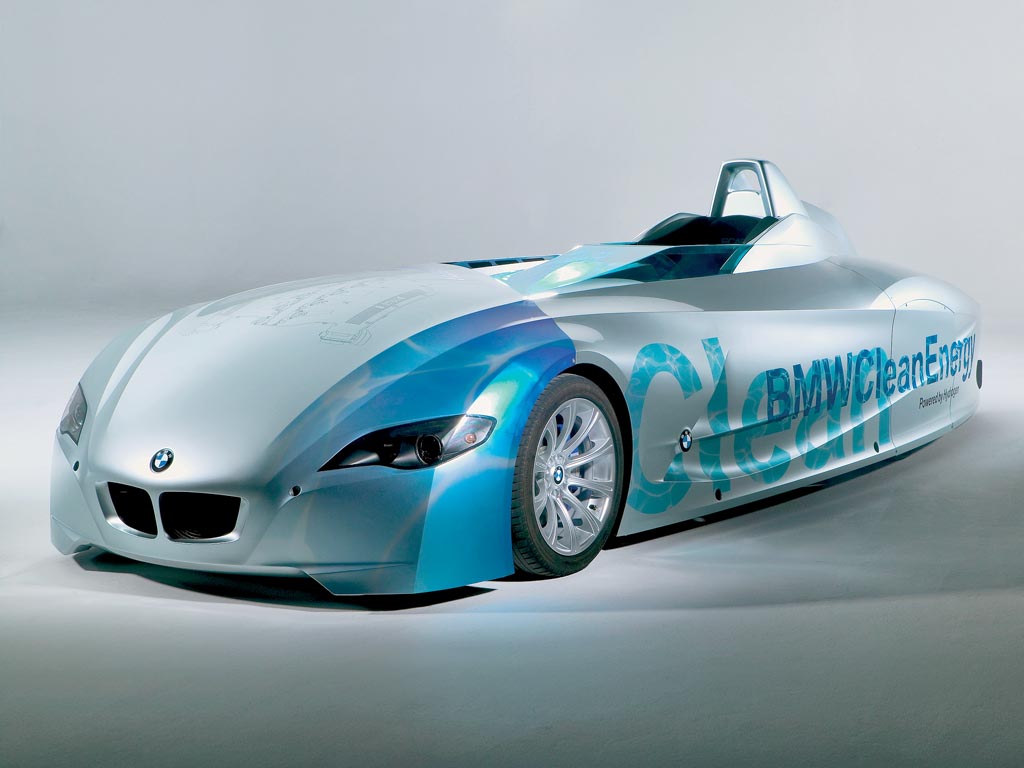

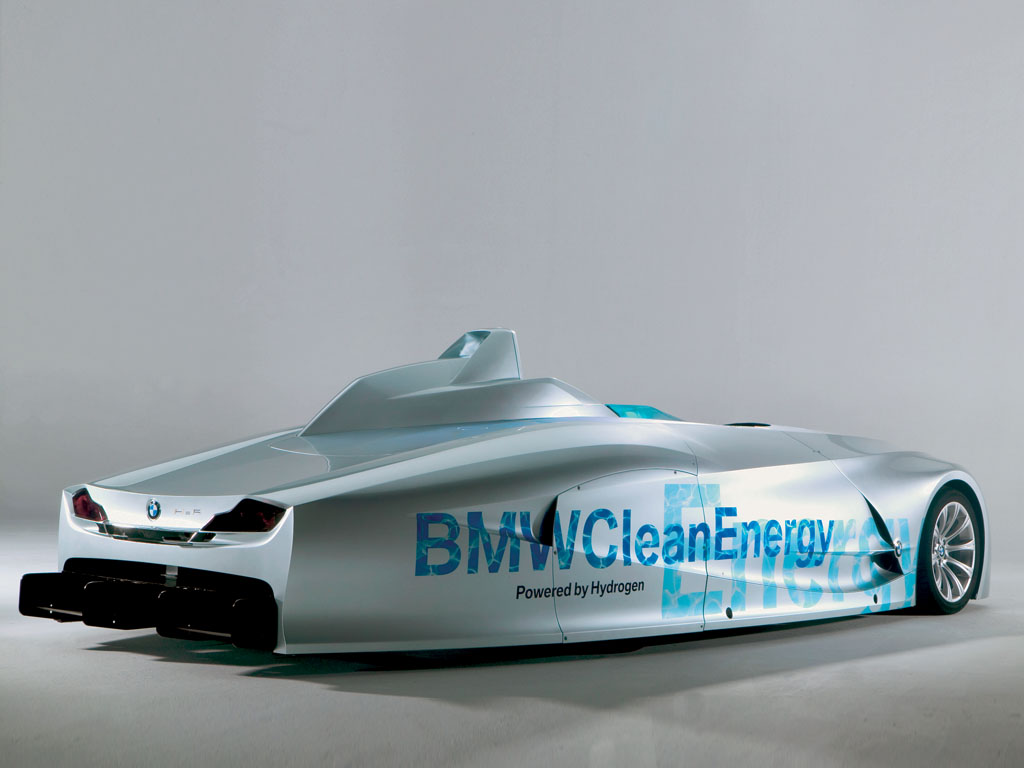

2004 BMW H2R Concept

BMW has proven what the hydrogen car is capable of, setting 9 records for cars powered by a hydrogen-fuelled internal combustion engine. ”BMW technology has already come a long way. Now, together with politicians and the energy industry, we must turn our vision of sustained mobility into reality”, stated Professor Burkhard Goschel, Board Member of the BMW Group. After achieving success at the high-speed Miramas Proving Grounds in France, the BMW Group has clearly proven its conviction that hydrogen is able to replace conventional fuel without requiring the driver to compromise performance.

The H2R prototype set up the following records shown here in terms of times measured and speed achieved:

| Record | Time in Seconds | Speed in Kph |

| Flying-start kilometre | 11.993 sec | 300.190 kph |

| Flying-start mile | 19.912 sec | 290.962 kph |

| Standing-start 1/8 mile | 9.921 sec | 72.997 kph |

| Standing-start 1/4 mile | 14.933 sec | 96.994 kph |

| Standing-start 1/2 km | 17.269 sec | 104.233 kph |

| Standing-start mile | 36.725 sec | 157.757 kph |

| Standing-start 10 miles | 221.052 sec | 262.094 kph |

| Standing-start kilometre | 26.557 sec | 135.557 kph |

| Standing-start 10 kilometres | 146.406 sec | 245.892 kph |

BMW works drivers Alfred Hilger, Jorg Weidinger and Gunther Weber took turns at the wheel of the Record Car in their record-breaking sessions.

BMW’s motive in setting up these records was not only to prove the power and performance the hydrogen engine is able to offer, rather, the reliability and durability of the technology used. In this process BMW is concentrating on the combustion engine, simply because the combustion power unit, given the sum total of all its features and characteristics, still offers the largest number of advantages and benefits.

The H2R Record Car

The specifications of the H2R Record Car include a six-litre 12 cylinder power unit developing an output of more than 210 kW or 285 bhp. Based on the gasoline power unit featured in the BMW 760i, BMW’s hydrogen combustion engine boasts technologies such as BMW’s fully variable Valvetronic valve drive.

The H2R Record Car benefits from the results gained in series development of BMW’s future hydrogen engine for the world’s first premium saloon built for dual-mode operation: BMW will be launching a dual-mode version of the current 7 Series during the production cycle of the present model, thus introducing the first car of its kind able to run on both hydrogen and gasoline.

The main modifications to the engine involve the fuel injection system adapted by BMW to the special features and requirements of hydrogen. Contrary to the production engine with fuel injected directly into the combustion chambers themselves, the injection valves in the hydrogen engine are integrated in the intake manifolds. For the specific speed record requirements to be fulfilled in this case, the hydrogen combustion engine was designed and built for single-mode operation running exclusively on hydrogen.

Hydrogen providing enhanced efficiency

A fundamental consideration is that the combustion properties of hydrogen are quite different from those of gasoline or diesel. Hydrogen burns faster, generates a higher temperature, has increased combustion pressure and combusts at a slightly lower temperature compared to conventional fuels. A significant advantage of the higher potency of the hydrogen/air mixture is that the generation of more power from the same amount of energy means a higher degree of efficiency.

Also, the H2R Record Car’s emissions are limited, for all practical purposes, to nothing but steam.

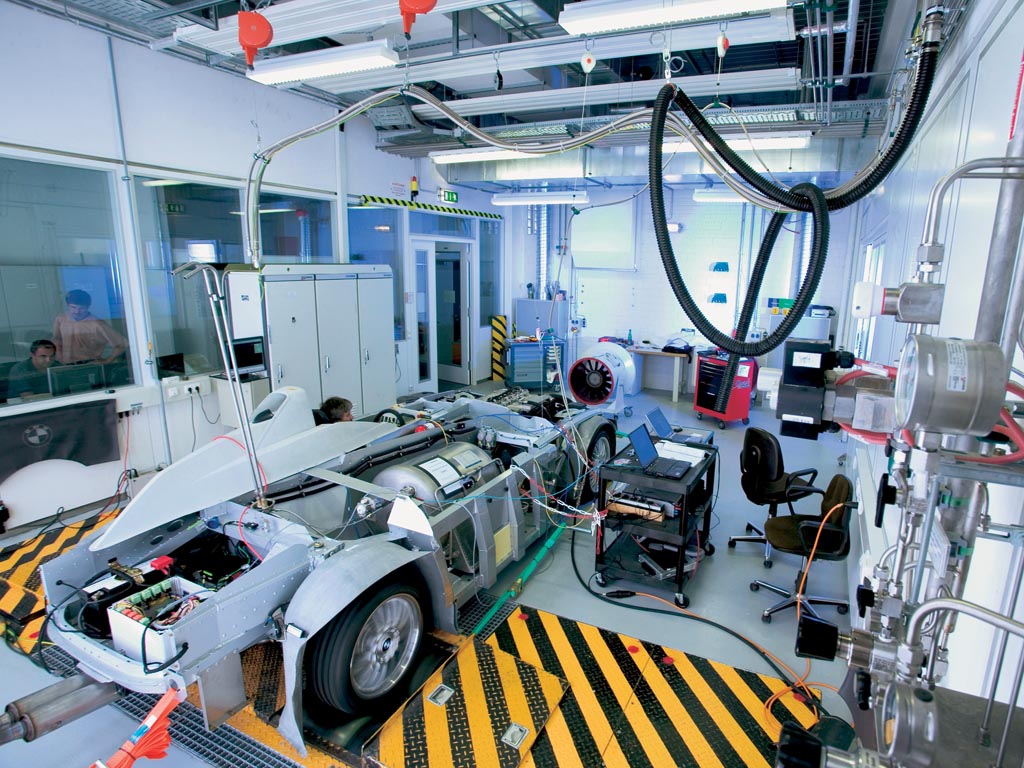

A Complex Fuel System

The fuel system featured in the BMW H2R Record Car is based on a proven series development concept. Fuel is filled into the tank of the H2R prototype at a mobile hydrogen filling station through a manual tank coupling. The vacuum-insulated, double-walled tank has a capacity of more than 11 kilos of liquid hydrogen and is fitted next to the driver’s seat. A total of three valves ensures optimum safety, the operating valve on the tank opening at a pressure of 4.5 bar.

To maintain optimum supply pressure on the injection valves at all times engine management reduces pressure in the supply pipe to approximately 1.2 bar by means of a control valve fitted specifically for this purpose.

To avoid misfiring BMW’s engineers have developed a specific gas cycle and injection strategy. Before the hydrogen/air mixture is able to flow into the cylinders, the combustion chambers are cooled by air to ensure that the fuel/air mixture is not able to ignite in an undesired, uncontrolled process.

With hydrogen being injected into the intake manifold as late as possible, the injectors have to meet very demanding requirements. Since gaseous hydrogen takes up a larger volume per unit of energy than liquid gasoline, the hydrogen injectors are larger than conventional units.

Safety valves rule out any dangerous consequences of possible leaks in the jacket around the tank serving to keep the hydrogen at the low temperature required, opening up as soon as pressure within the tank exceeds the limit of 5 bar. Four hydrogen sensors fitted at neuralgic points – for example in the tank itself and around the tank coupling – recognize any leakage immediately and inform the driver accordingly.

In Detail

| engine | Direct Injection Hydrogen V12 |

| displacement | 6000 cc / 366.1 in³ |

| body / frame | Carbon-Fibre-Reinforced Plastic Body over Monocoque Aluminum Spaceframe w/Front Aluminum SubFrame |

| front tires | 245/40 x 19 |

| rear tires | 245/40 x 19 |

| f brake size | mm / in |

| r brake size | mm / in |

| f suspension | Double Wishbone Spring/Strut Setup |

| r suspension | Multi-Link w/Anti-Roll Bar |

| curb weight | 1460 kg / 3219 lbs |

| length | 5400 mm / 212.6 in |

| width | 2000 mm / 78.7 in |

| gear ratios | :1 |

| drag | 0.21 Cd |