2013 Volkswagen Polo R WRC

Wolfsburg, 0 8 December 2012. Developing a competitive car for the FIA World Rally championship (WRC) is an extremely complex task. One minute it is c rouched low on smooth asphalt, the next it is travelling sideways on ice and snow, then it is tearing over rough gravel on tiptoes – then you have searing heat at one event and icy cold at the next. No other type of international motorsport offers such a wide range of climatic conditions and different surfaces . The cars in the World Rally Championship must overcome all these obstacles. Take this fine example of the flexibility that must be demonstrated by the car’s concept : there is a difference of about 10 0 mm between the ground clearance for gravel and asphalt. The chassis and engine must be as efficient as physically possible in the multitude of different conditions. Strong enough to take the strain, light enough to guarantee the necessary performance.

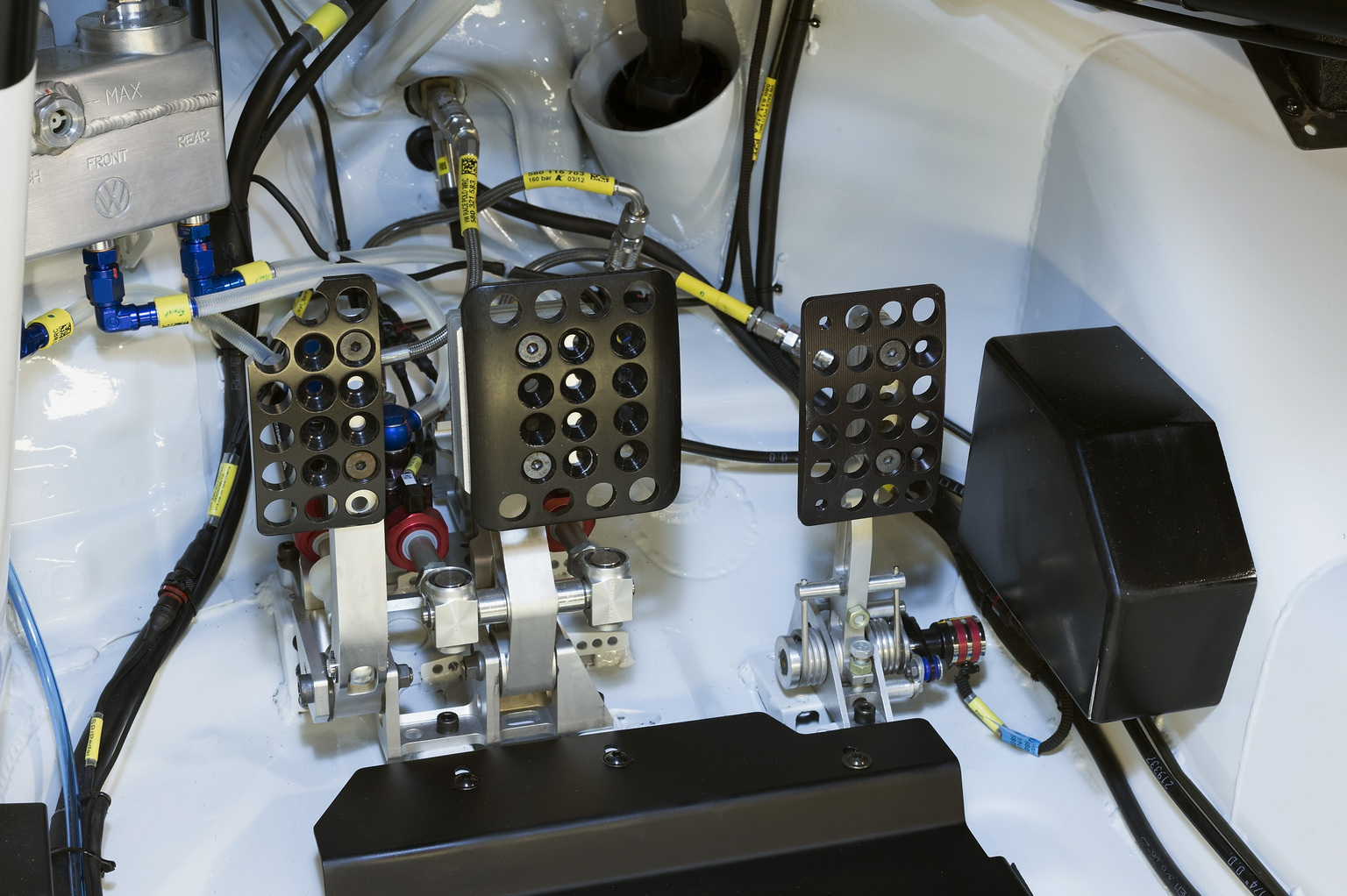

Development of the Polo R WRC

The Volkswagen engineers applied a minimalist approach during the 17 – month development of the Polo R WRC, which was based on the production Polo, from which the basic chassis was used. Every single component was subjected to numerous tests to determine the dimensions and weight, and was continuously improved over the course of the one and a half year development period . A strict schedule was adhered to, in order to ensure the homolog ated Polo R WRC was ready to be launched in time for the 2013 season: after the launch of the concept car in May 2011, Volkswagen initially tested a so-called 0 car as a component carrier , which completed its roll- out in the vineyards around Trier in autumn 2011. At the wheel of the concept car were Dr. Ulrich Hackenberg, Member of the Board of Management responsible for development, and rally legend Carlos Sainz .

The computer- assisted simulation of the first concept for the actual Polo R WRC began at the same time . The Volkswagen engineers then produced their own very special Christmas present: the first Polo R WRC was delivered to the foyer at Volkswagen Motorsport on Christmas Eve 2011. The roll- out followed at the Volkswagen test track in Ehra- Lessien in January 2012. Initial tests were also performed in Sweden and Spain. From March onwards , the technician s performed constant modificati o ns to the Polo R WRC. This included work on issues such as chassis kinematics and the lightweight construction of the car. The assembly of this improved version of the Polo R WRC, which will line up at the 2013 Rally Monte Carlo, ultimately began in September 2012 .

2013 Volkswagen Polo R WRC Gallery

2013 Volkswagen Polo R WRC Gallery

Powered by Wolfsburg

Every single component on the Polo R WRC underwent a series of fundamental processes on its way to attaining the “ready to race” status. First up was the theory: the parametric design process on CAD (computer aided design) systems is verified by computer- aided simulations (e.g. CFD – computer fluid dynamics) and tested in practice in wind tunnels and the Volkswagen Group’s altitude environmental test chamber. Only then did the extensive test drives follow. The resources available in Wolfsburg play a key role in designing and testing the chassis . Volkswa gen’s Design department made a significant contribution with valuable development work focussing on crash tests and safety. Tests on the car in wet conditions were also made possible by the engineers at the headquarters in Wolfsburg.

“Experience plays a major role when developing the chassis,” said François – Xavier Demaison, Technical Project Manager WRC. “ The know- how acquired in previous years allows you to take short cuts without going through a long simulation and test phase that would otherwise be necessary. This is the case, for example, when it comes to ground clearance, kinematics, suspension or the configuration of the differential. For example, you can spend many kilometres slowly adjusting the dimensions of the undercarriage until you find the optimal configuration. It saves an awful lot of time if you already know how strong you need to make a part . ”

The result, under the guidance of Volkswagen Motorsport, is a high – tech jigsaw consisting of about 3,000 pieces, of which 1,360 were designed from s cratch for use in motorsport – not including the engine and gearbox .

state- of – the – art engine

When designing the Polo R WRC’s engine, which consists of around 300 individual parts, Volkswagen took a completely different approach to that used in the development of the chassis. The result is the 315 – hp, 1.6- litre engine . The automated interplay between CAD design and simultaneous simulation using CFD processes led, among other things, to the optimal design of the intake ports . Volkswagen took a strictly analytical approach to decisions for or against various concepts within the strict regulations of the World Rally Championship.

Over the course of the development process, the Engine Development department at Volkswagen Motorsport tested all the options permitted by the regulations and simulated their dependence on each other. “To a very large degree, the engine for the World Rally Championship has been designed using electronically- aided development methods , in order to ensure that the right decisions were made, ” said Dr. Donatus Wichelhaus, Head of Engine Development at Volkswagen Motorsport. “The cooperation of our colleagues in Volkswagen’s Production and Research departments was invaluable here. They were of great assistance, particularly in the automated development steps during the design phase – such as those used for the intake geometry.”

Throughout the entire process, Dr. Wichelhaus’s team of engineers checked a wide range of different solutions. Two different st roke/bore ratios, three different cylinder head concepts, nine different intake port geometries, countless injector variants, and two different valve diameters were checked, with the best solutions selected for the final engine. This general approach resul ted in a largely problem – free engine development, which produced impressive test results right from the outset . The so- called anti – lag system to reduce turbo lag received particular praise from the Volkswagen drivers during testing.