2010 McLaren MP4-12C

The McLaren MP4-12C is revealed as the first in a range of high-performance sports cars from McLaren Automotive, the independent car division based at the McLaren Technology Centre in Woking, England. The 12C, and future models within the range, will challenge the world’s best sports cars, benefiting from the expertise and virtuosity of the McLaren Group.

Twenty years of sports car design, engineering and production combined with inspirational success in Formula 1 have driven Ron Dennis, McLaren Automotive Chairman, to announce his plans for the ultimate line-up of technology-led and customer-focused performance cars for the 21st century. The rules in the sports car world are about to be re-written.

Through a rich modern history, McLaren’s automotive division has already built the world’s most critically acclaimed supercar, the McLaren F1 (1993-1998) and the world’s best-selling luxury supercar, the Mercedes-Benz SLR McLaren (2003-2009). McLaren Automotive now looks to the future with a new range of revolutionary sports cars.

“It is a long-held dream of mine to launch high performance sports cars that set new standards in the industry,” said Dennis.

“We began designing and building cars for aficionados of thoroughbred sports cars almost 20 years ago. Incorporating the leading edge technologies that the McLaren Group has built up within its various companies, I believe we are now perfectly placed to open up this new chapter in McLaren’s history as well as play a part in the regeneration of high-tech manufacturing in the UK and global automotive environment,” he concluded.

At its heart, the McLaren MP4-12C features a revolutionary carbon fibre chassis structure, the Carbon MonoCell: the first time a car in this market segment is based around such a strong and lightweight racing car engineering solution and the first time any car has ever featured a one-piece carbon fibre structure.

This step change in sports car design means that the 12C introduces new standards not just in handling, ride and outright performance, but also safety, economy and practicality in an already competitive sector.

Martin Whitmarsh, Team Principal of McLaren’s racing team highlighted the integral part that McLaren’s motorsport and road car experience played in developing the 12C: “McLaren has for years offered a potent mix of race car and road car technologies. This combination of McLaren’s performance heritage, and future demands on what is expected of high performance sports cars in the 21st century, gave us a head-start when we embarked on this project. The 12C, and future variants, draws on the spirit of Formula 1 and delivers real-world technological advances.”

The first car from the new company, the McLaren MP4-12C, is a high performance two-seat mid-engine model in the ‘core’ sports car market segment for cars costing between £125,000 and £175,000. The 12C is pure McLaren, featuring no carryover parts from any other car, and will be produced by McLaren in the UK. It goes on sale through a dedicated, worldwide retailer network in early 2011.

“McLaren is already a car maker with maturity and experience, having produced iconic cars such as the F1,” said Antony Sheriff, McLaren Automotive Managing Director.

“The next step was to construct a range of pure McLaren high performance sports cars that are true to the company’s philosophy and reflect our position as an absolute technology and performance leader. So, when we embarked on the 12C project, we wanted to re-write the rules of sports car design. Indeed, the 12C offers performance and technology that exceeds that of the world’s most expensive and sophisticated supercars, while competing in a much more accessible market segment. And to achieve this result, we designed every component from scratch to meet the extreme goals of the 12C and avoid any compromise.”

“Forget what you know about sports car companies, McLaren is different,” he concluded.

Inside out

The heart of the new car is the Carbon MonoCell. McLaren pioneered the use of carbon composite construction in the 1981 Formula 1 MP4/1 model and set a trend that all Formula 1 teams have followed. The company brought carbon fibre to road cars for the first time with the 1993 McLaren F1 and then built on this experience with a carbon fibre chassis and body on the SLR manufactured to the same exacting standards, but in higher volumes.

So, until now, carbon chassis have remained the preserve of the most expensive exotic cars; a purchase for the super-rich where costs are driven by the complexity of carbon fibre chassis design and build.

The 12C changes this by introducing the advantages of carbon composite – light weight, high strength and torsional rigidity, and longevity – to a more affordable sector through its revolutionary engineering as a one-piece moulding. Never before has a carbon fibre chassis been produced this way.

The 12C MonoCell not only brings dynamic benefits, but also offers fundamental engineering opportunities that form the basis of the car’s unique character. It has been designed to allow a much narrower structure overall which in turn contributes to a more compact car that is easier to position on the road and more rewarding to drive.

Not only is the 12C unique in its class by offering carbon technology, it also has the highest specific power output as well as extraordinary power- and torque-to-weight ratios. Furthermore, the Proactive Chassis Control system offers groundbreaking handling and ride comfort while an intense focus on occupant packaging offers new levels of comfort and everyday usability.

Antony Sheriff explained. “With the 12C we are redefining the relationship between performance and practicality, as well as performance and efficiency, achieving leading positions in both. We have designed this car from the inside out. We have a saying in McLaren – ‘everything for a reason’ and the 12C will surprise people in many ways.

“A clear illustration of its special qualities is in the efficiency of its power delivery. With the 12C’s power output of around 600hp and its low CO2 emissions, it delivers the highest horsepower to CO2 ratio of any car on the market today with an internal combustion engine…and that includes petrol and diesel hybrids,” Sheriff concluded.

Pure McLaren

All the parts of the McLaren MP4-12C are bespoke and unique to this car. Everything from the engine right down to the tailor-made switches and buttons is pure McLaren: nothing has come from another manufacturer’s parts bin.

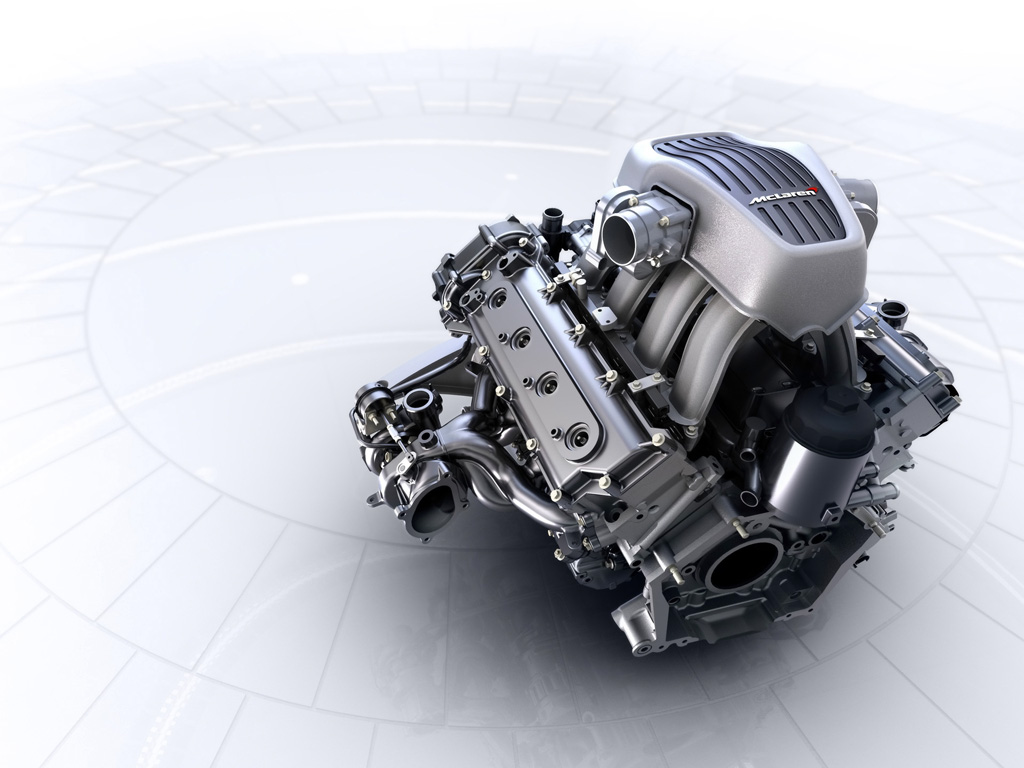

The 12C is powered by a bespoke McLaren ‘M838T’ 3.8 litre, V8 twin-turbo engine producing around 600bhp, driving through a McLaren seven speed Seamless Shift dual clutch gearbox (SSG). It is targeting not only new standards for power and performance in its sector, but also class-leading fuel economy and CO2 emissions; supported by McLaren’s experience of active aerodynamics to aid cooling, grip, handling and road holding.

“The 12C is all about performance,” said Sheriff. “And in McLaren, we have a very broad definition of performance. We don’t just look at the traditional one-dimensional parameters like top speed, we focus equally on useable measures such as in-gear acceleration times, braking performance in all conditions, and efficiency of power delivery combined with the lowest possible fuel consumption and CO2 emissions. Sure, 12C is very fast, but it is also the most efficient, most driveable high-performance sports car in the world.

“In the more subjective areas of road-holding, handling, comfort, driver involvement and day-to-day usability, McLaren is achieving new standards for a mid-engined high performance sports car in this sector,” he concluded.

Thorough engineering and market research led to concept development and a clear decision in favour of a mid-engined two door high performance sports car. Intensive work was carried out in the wind tunnel and the driving simulator to ensure that the new car would inherently have superb dynamic qualities.

Dick Glover, McLaren Automotive Technical Director, was closely involved with the development of these invaluable tools during his time with McLaren’s Formula 1 race team.

“There are so many examples of race car process and technology transfer in the 12C,” claimed Glover. “The car owes much to McLaren’s experience and success in motor sport. The advantage of technology transfer is only one element; speed of decision-making and development, F1 processes and people all make an important contribution.

“Brake Steer, for example, is a technology we pioneered on our Formula 1 car back in 1997. It helps to dial out understeer on entry to a corner and improves traction on the way out. Another is the Pre-Cog function on the gearshift rocker that effectively primes the gearbox ready for the next change, ensuring a more satisfying and faster gearchange. This is a high performance sports car with race car genes and teamwork at its heart.”

Adding lightness

Weight is the enemy of performance in every area of car design. It affects acceleration, speed, handling, fuel consumption and CO2 emissions – everything. McLaren Automotive engineers pursued weight saving obsessively. For example:

• The Carbon MonoCell not only reduces the weight of the structure but also allows for the use of much lighter weight body panels.

• The close position of the driver and passenger allows a narrower, lighter body while giving improved visibility with a clearer perception of the car’s extremities.

• Brakes with forged aluminium hubs save 8 kg and weigh less than optional carbon ceramic brakes.

• Lightweight exhaust pipes exit straight out the rear of the car, minimizing their length and weight.

• Airflow-assisted Airbrake deployment dramatically reduces weight of the Airbrake activation system.

• Small, compact downsized engine coupled to lightweight compact SSG minimizes vehicle length, weight and polar moment of inertia.

• Significant weight was pared off the alloy wheels through intensive Finite Element Analysis of wall thicknesses.

• The engine cooling radiators were mounted at the rear, as close to the engine as possible, to minimize the pipework, the fluids contained within them, and therefore weight. They were also mounted in car line to minimize vehicle width.

“We have spent most of the programme ‘adding lightness’,” said Mark Vinnels, McLaren Automotive Programme Director. “If the cost of reducing weight brought performance gains in speed, handling or economy, we did it. However, if the expense could deliver improved performance elsewhere we didn’t pursue it. We never set weight targets as such; we set cost-to-performance targets and examined everything in this way.

“A good example of this philosophy is that we considered carbon fibre body panels. They would have reduced weight but added little benefit as the new one-piece Carbon MonoCell provides all of the torsional strength the body needs. The costs saved were used elsewhere for greater weight reduction and efficiencies overall. This was the holistic approach to weight saving that we used all the way through development,” he concluded.

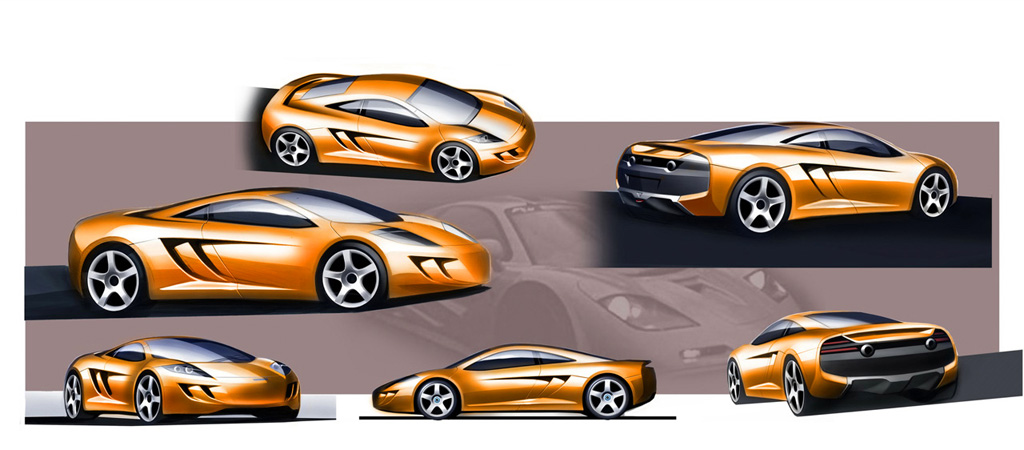

Design: everything for a reason

The McLaren MP4-12C design follows similar principles to McLaren’s Formula 1 cars, and the legendary McLaren F1, where everything is for a reason and all lines, surfaces, and details are designed with a job in mind as much as styled. This ensures that the 12C communicates its engineering through its styling and will remain timeless as a piece of automotive design.

Frank Stephenson, McLaren Automotive Design Director: “Many sports cars and super cars present an ‘in-your-face’, ‘look-at-me’ image that can become wearing and boorish; the ultimate backhanded compliment becomes, “…it was of its time”. Great design, however, is timeless and looks relevant years later. Take the McLaren F1 as an example. I hope that with the 12C we have produced a car that looks great today and will still look great in years to come.”

The 12C’s body has been styled to support sector-leading levels of downforce; downforce that then subsequently contributes to sector-leading levels of lateral grip and stability. Air flow has been manically managed to support all performance figures and light weight targets. For example, placing the radiators adjacent to the engine keeps the car narrow and reduces weight. However, this results in a huge challenge of ensuring ample air flow to the radiators. The result? The large side air scoops and integrated turning vanes that are dramatic, but purely functional. No larger or smaller than required.

The designer’s challenge is to then take that styling purpose driven by engineering aspirations and add personality. That’s why the air scoops resemble the McLaren logo in form, as do other features around the car.

Just two ‘pure’ lines flow round the car and, when combined with the integration of several dramatic convex and concave surfaces, present a car that looks compact, low and well proportioned.

The market opportunity for McLaren

“I am confident that now is the right time for McLaren Automotive to become a full line high performance sports car manufacturer,” stated Ron Dennis.

“Worldwide demand for high performance cars is strong, in large part because of great cars from great competitors. With McLaren joining that list, it will grow stronger still. What we are offering is a new approach to the market, through a skilled, solid, debt-free and risk-managed company. McLaren is right to take this step now and support future growth of high-technology manufacturing and engineering jobs in the UK,” Dennis declared.

The market for high performance sports cars has grown substantially since the turn of the century. McLaren divides the market into segments that encompass both more comfort–orientated GT cars and the hard-edged supercars for road and track use.

The ‘core’ segment runs from around £125,000 to £175,000 featuring such cars as the Ferrari 458, Lamborghini Gallardo, Porsche 911 Turbo, Bentley Continental GT and Aston Martin DB9. A second segment is the ‘high’ category with prices ranging from £175,000 to £250,000 and consists largely of front-engined GT cars such as Ferrari’s 599 GTB and 612, with just one mid-engined contender, the Lamborghini Murcielago.

The final segment is the ‘ultimate’ group, a sector more or less initiated by the McLaren F1 in 1993 and now populated by a select group of cars including the Mercedes-Benz SLR McLaren, Bugatti Veyron, and cars from the likes of Pagani and Koenigsegg that followed legends such as the Porsche Carrera GT and Ferrari Enzo. In 2011, McLaren will bring technology and performance exclusive to this ‘ultimate’ sector into the ‘core’ segment.

Although the recent economic downturn has affected the performance car sector, just as it has the entire motor industry, McLaren Automotive believes that the ‘core’ segment’s growth from 8,000 sales in 2000 to more than 28,000 in 2007 highlights the potential that exists and that it will soon return to at least 2007 levels.

“By the time the 12C is launched in 2011 we expect the economic conditions to be much improved. We have already seen significant interest in the car and the supply of the 12C will be relatively scarce; in its first year we plan to produce just 1,000 cars which represents only 3.5 per cent of the ‘core’ market,” explained Antony Sheriff.

“We have created ground-breaking new technology, lightweight engineering solutions, and harnessed real-world motor racing applications. It brings new levels of performance, fuel efficiency and practicality to the 12C’s segment. And it will be more exclusive than its principal competition with a price that reflects its lack of ubiquity,” he said.

McLaren Automotive will distribute the 12C and future models through a brand-new retail network in all global markets.

Exclusivity, exquisite design and a passionate focus on delivering a wonderful ownership experience will ensure that the small number of retailers around the world are taking on an attractive new brand. This approach will drive excellent customer service and a virtuous circle that retains McLaren customers and brings in new converts as the range expands.

McLaren MP4-12C – what’s in a name?

The name of the new McLaren sports car is MP4-12C.

What does this signify? As one might expect at McLaren, everything has a purpose and the nomenclature is no exception.

• ‘MP4′ has been the chassis designation for all McLaren Formula 1 cars since 1981. It stands for McLaren Project 4, resulting from the merger of Ron Dennis’ Project 4 organisation with McLaren.

• The ’12’ refers to McLaren’s internal Vehicle Performance Index through which it rates key performance criteria both for competitors and for its own cars. The criteria combine power, weight, emissions, and aerodynamic efficiency. The coalition of all these values delivers an overall performance index that has been used as a benchmark throughout the car’s development.

• The ‘C’ refers to Carbon, highlighting the unique application of carbon fibre technology to the future range of McLaren sports cars.

The elements of this name represent everything that the McLaren MP4-12C stands for:

• ‘MP4’ represents the racing bloodline

• ’12’ represents the focus on complete performance and efficiency

• ‘C’ represents the revolutionary Carbon MonoCell

“We are very proud of the McLaren MP4-12C and all the teamwork, intelligent thought and sheer effort that have gone into developing this car. What drives people at McLaren is passion – if you cut them, they bleed McLaren. And there is no doubt in my mind that the 12C fully reflects that focus, drive and determination in its performance, style and ownership potential,” said Ron Dennis, McLaren Automotive Chairman.

“This is the start of an exciting new chapter in McLaren’s history, in British high-technology engineering and manufacturing, and in global sports car design. We aim to be the best, but will leave that ultimate judgement to our first customers in 2011. Until then, we will strive to put one name at the top of the ‘most wanted’ list for buyers of high performance sports cars: ‘McLaren’,” he concluded.

The McLaren MP4-12C: inside and out, and in detail

A carbon fibre heart

Light weight and performance are defining philosophies at McLaren. But outright power alone is of little significance if a car’s weight saps output or if that power is unmanageable and compromises the driving experience or results in unacceptable emissions.

Fundamentally, it is critical to keep weight as low as possible. Increased customer demands for safety and advanced features all mean that shaving weight is ever more difficult. However, at McLaren saving weight remains a passion and at the heart of the McLaren MP4-12C is a carbon fibre composite chassis: the Carbon MonoCell.

This revolutionary structure is the automotive version of a McLaren innovation that started with Formula 1 back in 1981 and delivers both weight savings and performance gains. It is a technology cascade in which McLaren brought carbon composite technology from the aerospace industry to make the MP4/1 F1 car, the first Formula 1 car to benefit from the strength, weight and safety of carbon fibre.

McLaren’s Formula 1 carbon fibre technology then offered the company the opportunity of applying its expertise to road car applications. The first ever road car to be constructed of this material was the McLaren F1 produced in 1993, albeit in small numbers. The F1 was followed by the Mercedes-Benz SLR McLaren that also shared this rare expertise.

Only a handful of other cars in the market offer such technology today and all of them lie in the ‘ultimate’ segment. No manufacturer has brought the advantages of carbon composite technology to a more affordable sector of the market. But the 12C does, through engineering passion and a relentless pursuit of efficiency.

So, McLaren did it first with the F1, the world’s fastest car for many years, then in the highest volume with SLR, which almost doubled the volume of the next highest produced carbon fibre-based high performance sports car by selling over 2,100 units. Now, through revolutionary one-piece moulding of the MonoCell, McLaren brings a carbon composite chassis down to the ‘core’ category, where currently only traditional metal structures are offered.

The advantages this technology brings are light weight, high torsional rigidity, a very strong safety cell, low perishability, ease of repair and extreme dimensional accuracy.

The 12C MonoCell weighs less than 80 kg. Carbon fibre contributes to the car’s low overall weight and it forms the structural basis for the whole car. The tub’s torsional rigidity is considerably stiffer than a comparable alloy structure.

This inherent lack of flex means the unique front suspension system, which is mounted directly onto the MonoCell, requires less compromise for flex of the suspension itself. Therefore, it is easier to develop the unique balance between fine ride and precise handling that McLaren has targeted. The MonoCell also offers greater occupant safety. It acts as a safety survival cell, as it does for a Formula 1 car.

Carbon composites do not degrade over time like metal structures that fatigue. One is able to get into a 15-year-old McLaren F1 and there is none of the tiredness or lack of structural integrity that afflicts traditional cars that have suffered a hard life. The 12C will feel as good as new in this respect for decades.

And in the event of an accident, the light weight aluminium alloy front and rear structures are designed to absorb impact forces in a crash and can be replaced relatively easily. Aluminium extrusions and castings are jig welded into the finished assembly and bolted directly to the MonoCell. Cars with full aluminium chassis use their structure to absorb and crumple on impact, which implies more fundamental damage (and expense) to the whole structure, including the passenger cell, in a major accident.

McLaren has pioneered a new carbon fibre production process that allows the MonoCell to be produced to exacting quality standards, in a single piece, in only four hours, compared to the dozens of carbon components (and dozens of production hours) that normally feature in a carbon fibre chassis structure. This naturally brings huge efficiency and quality benefits. The MonoCell project is managed by Claudio Santoni, McLaren Automotive Body Structures Function Manager.

“It was clear that we needed to develop a car with a carbon fibre structure. After all, McLaren has never made a car with a metal chassis!” said Santoni.

“The whole 12C project is based on the concept of the MonoCell. This means that McLaren can launch into the market with greater performance than our rivals and a safer structure. To put it into perspective, if the costs and complexity of producing a McLaren F1 carbon fibre chassis are taken as a factor of 100, the 12C chassis production costs are reduced to a factor of seven or eight, without degrading the strength or quality of the carbon fibre structure. And this step-change in technology could make its way into more mainstream cars,” he concluded.

Getting the production process right is the result of five years of extensive research. Now that the process is perfected, it allows McLaren to produce the MonoCell repeatedly at very high quality.

“Not many people in the automobile world work to standards demanded by the aerospace industry,” claimed Mark Vinnels, McLaren Automotive Programme Director.

“Our ability to analyse and predict the performance of carbon fibre is in line with aerospace technology and is truly world class, particularly in the sense of predicting failure, which is obviously key in managing crash events and passive safety.

“We can now predict failure levels at individual ply level in the carbon composite and the results are absolutely correlating with what we predicted,” he concluded.

The finished MonoCell emerges in one piece and this new process could revolutionise car design. It avoids the need to bond different parts to make the whole structure, as with all other carbon fibre cars. It is hollow, saving further weight, and the integrity of production ensures the location of suspension and ancillaries is accurate to the finest of tolerances.

Powertrain: pure McLaren

The McLaren MP4-12C is powered by a twin-turbocharged, 3.8 litre 90_ V8 engine – the ‘M838T’. This marks the start of a new era in ‘core’ segment sports cars – smaller capacity, lighter weight, higher efficiency and more economical power units. The engine has the highest specific power output in its segment which, when allied to its low weight carbon composite chassis, delivers exemplary power- and torque-to-weight ratios.

‘M838T’ is a unique McLaren power unit, developed specifically for the 12C. It is compact, lightweight, very stiff, and offers an uncompromising combination of very high performance and good driveability, with excellent economy and CO2 emission values.

Taking power and emissions in combination (measured by its horsepower to CO2 ratio), the 12C delivers its power at greater efficiency than any other car on the market with an internal combustion engine, including hybrids.

‘M838T’ features dual variable valve timing and produces around 600bhp and 600Nm of torque. A dry sump and flat plane crankshaft allow the engine to be placed extremely low in the chassis thereby lowering the centre of gravity and improving handling responses. It also features composite cam covers and intake manifolds, which reduce weight and heat transmission into the charge air, as well as Nikasil-coated aluminium liners for further weight reduction.

The McLaren engine revs to 8,500rpm, has quick transient throttle response and delivers its abundant torque throughout the rev range. A staggering 80 per cent of torque is available at below 2,000rpm, ensuring great driveability and no need to floor the throttle to deliver performance.

And it delivers a great soundtrack to highlight the engine’s performance, flexibility and driveability. The sound of the engine has been thoroughly engineered through exhaust manifold design and tuning of the exhaust and intake systems to deliver a unique engine note.

The high level exhaust pipes exit through a mixing box, rather than a conventional and heavy silencer box. All parts of the exhaust system up to the mixing box feature sandwich layer heat-shielding that helps reduce heat from the engine bay. In just an 18mm gap, exhaust gas temperatures reduce from 900OC to 300OC.

The engine drives the rear wheels through two wet clutches and a McLaren-developed seven speed Seamless Shift dual clutch gearbox (SSG).

The Seamless Shift technology offers variable programmes ranging from ‘normal’ for road use and ‘sport’ for quicker changes still, right up to a lightning quick high performance mode. In addition an ‘automatic’ mode, ‘launch control’ and ‘winter’ modes can be selected, the latter changing all electronic functions to suit low friction conditions and delivering maximum driver aid and support. There is no traditional manual transmission offered; the two pedal layout offered further scope to create a narrow, and therefore light, car.

The 12C’s SSG is a development on the automated and sequential manual gearboxes with paddle shifts that proliferate in the car market today. The character of the transmission will engage even experienced drivers with its responsiveness and its contribution to the whole dynamic package.

With minimal torque loss, there is none of the lurch, hesitation or unpredictability that characterise traditional automated-manual transmission systems.

Design of the SSG system was driven by a demanding mechanical package that not only reduced weight and improved dynamic control for the entire vehicle, but also delivered driver benefits.

It is lightweight and compact in design and positioned in exactly the best location. The input shaft lies very close to the output shaft to help position the entire powertrain low in the vehicle. Twin secondary shafts ensure any rear axle weight overhang is minimised and rear crash performance is uncompromised. The bespoke SSG is further complemented by an entirely new control system.

This obsessive attention to detail comes as second nature to McLaren, but is not just there to satisfy the engineers’ passions. McLaren’s designers have also engineered the system to work seamlessly with the driver.

The system reduces weight and benefits packaging targets, but also ensures that driving programmes and shift strategies take the driver’s own inputs and uses them to directly control the engine’s torque and speed to deliver performance, economy or comfort as requested.

Gears are changed using a Formula 1 style rocker shift that pivots in the centre of the steering wheel. It is actuated on either side of the steering wheel (pulling right changes up, pulling left down).

As with the McLaren Formula 1 car, a shift can be actuated either by pulling or by pushing on the rocker. The rocker moves with the steering wheel, rather than being mounted on the steering column, so that if a gearchange is needed while lock is being applied the driver does not have to fumble around to change gear.

The rocker itself incorporates an innovative feature created by McLaren engineers called Pre-Cog. The name stands for pre-cognition, literally ‘foreknowledge’. The rocker on the 12C has two positions with a slightly different haptic (or feel) for each. The driver applies first pressure to the rocker and it informs the gearbox to get ready to swap ratios, thereby saving time – latency – between the message being sent and the gearbox being primed to act. The second pressure confirms that the gear should be changed and the torque handover is completed in milliseconds.

“What Pre-Cog actually does is initiate the shift process by priming the clutch and torque handover – it takes significant time out of the process,” explained Dick Glover, Technical Director McLaren Automotive.

“It’s a little bit like the first pressure on a camera shutter button. There’s no requirement for the driver to use it but it is more satisfying and engaging if you do. The SSG also promotes seamless shifting in which the driver doesn’t have to reduce engine power at all – rather than the gearshift slowing you down, it actually speeds the car up by recovering the energy of the crank spinning as it drops engine speed,” he said.

In practice the latency of the shift is virtually zero, the actual gear change time is very fast and the level of impulse can be varied according to the gearbox mode. Considering that McLaren was the first Formula 1 team to introduce seamless shift gearchanges into motor racing, it was a natural step to develop such a bespoke transmission to its sports car project.

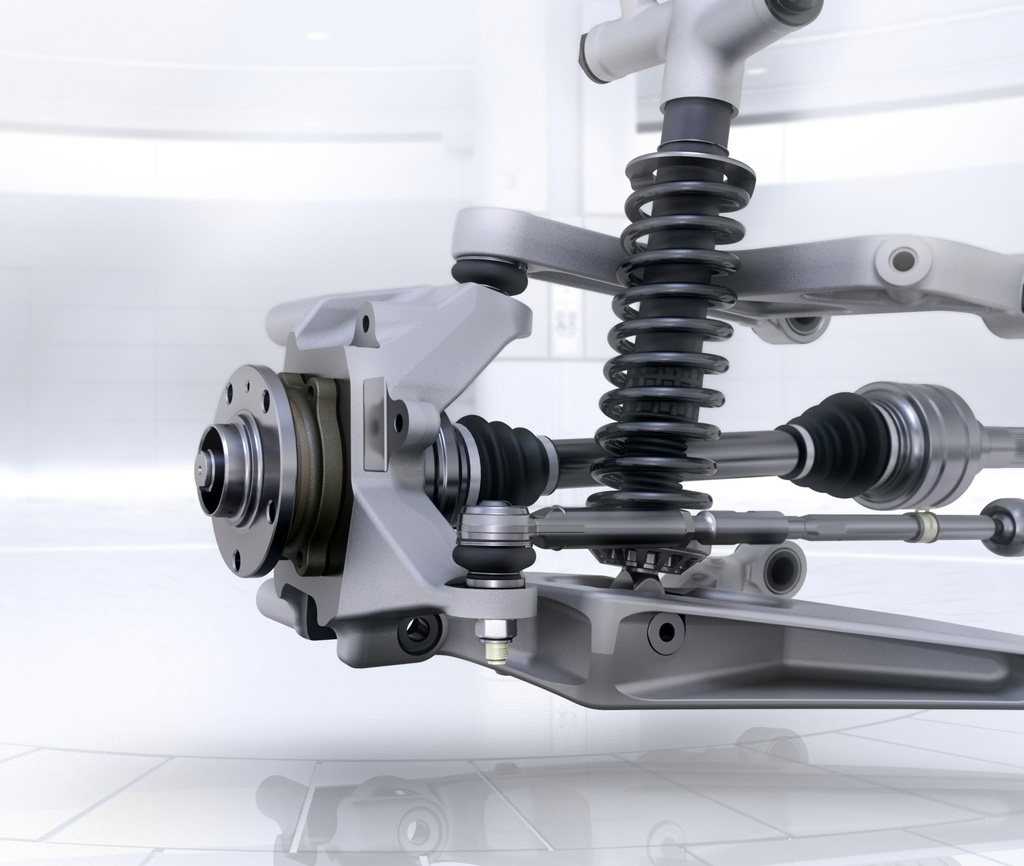

Chassis: Proactive control

The suspension for the McLaren MP4-12C breaks new ground, offering hitherto unseen levels of roll control and grip (an almost flat cornering attitude, depending on the programme selected).

Although such track-like responses would normally imply a rock-hard ride, the 12C delivers compliance and ride comfort more akin to an executive saloon car. The mix of occupant cosseting and sporting potential is truly unique. The 12C offers the driver both class-leading ride comfort and class-leading performance.

The whole chassis package produces not only a unique relationship between ride and handling, but also astonishing lateral grip and outstanding traction. The 12C is poised and balanced whether negotiating high or low speed corners, during direction changes, under heavy or light braking and on tightening or opening corners.

The trick behind blending such opposing objectives lies in the innovative Proactive Chassis Control system, uncompromised geometry, and weight distribution.

The suspension is based on double wishbones with coil springs. The dampers are interconnected hydraulically and provide adaptive responses depending on both road conditions and driver preference.

The Proactive system features adjustable roll control which replaces the mechanical anti-roll bars that have been a standard feature of road cars since time immemorial. It allows the car to maintain precise roll control under heavy cornering while decoupling the suspension in a straight line for excellent wheel articulation and compliance.

There are three suspension modes that are selected on the Active Dynamics Panel. As with the powertrain adjustment, there is a ‘normal’, a ‘sport’ mode and a high performance mode which adjusts numerous parameters in the system.

Not only is the Proactive suspension a unique application that delivers absolute benefits to driver and passenger, but it is also another example of McLaren’s drive to achieve all-round performance goals from core engineering targets.

For example, the unique blend of a compliant ride with ultra-sharp handling also delivers ownership benefits as it protects suspension bushes from wear and tear, with McLaren’s research suggesting a potential for up to ten times more mileage than on some competitor cars. Also, the hydraulic pump that supports the dampers is the same pump that supports the electro-hydraulic steering system. Why use two pumps when one – small and lightweight – pump will do?

The powertrain packaging also contributes to the 12C’s handling prowess.

The engine is mounted low down in order to lower the centre of gravity while the radiators are rear-mounted and reduce weight by saving on long piping to and from the engine (and the fluids they would hold). The value of rear-mounted radiators is key to the 12C’s handling and balance. The more weight that can be concentrated within the wheelbase and towards the centre of gravity, the lower the polar moment of inertia, thereby improving corner turn in.

Another feature that helps the 12C to handle at a new level is a development of an electronic system used by McLaren’s 1997 MP4/12 Formula 1 car, – Brake Steer. In essence, it is a system that brakes the inside rear wheel when the car is entering a corner too quickly to make the desired radius. Under normal circumstances the front would wash away wide of the apex the driver wants to touch: in other words, the car is in a state of understeer.

Brake Steer manages the tendency of a car to wash out and brings its nose back on line. It assesses the steering angle to determine the driver’s intended course and applies the inside rear brake to increase yaw rate and resume the desired course.

The system also works on acceleration out of a corner when the inside rear has a tendency to spin, allowing the driver to put power down more quickly. It controls what a limited slip differential would do and obviates the need for such a complex and heavy unit, thus saving more valuable kilos.

The standard brakes for the 12C reduce overall vehicle and unsprung mass. McLaren has developed a composite braking system that uses a forged aluminium bell that attaches to the cast iron disc. This solution maintained the excellent brake feel of a cast iron disc while saving 8 kg. Carbon ceramic brakes will be available as an option, offering fade-free braking performance during high performance driving, but the standard composite brake system is actually lighter than the larger carbon ceramic units.

The design of the standard cast alloy wheels (19″ front, 20″ rear) was driven by McLaren’s light weight objectives: the light weight styling was agreed in concept, then the wheel was tuned using Finite Element Analysis to take a further 4 kg out of the wheels. Bespoke Pirelli tyres have been developed in conjunction with McLaren specifically for the 12C.

An array of electronic aids is fitted to the 12C that will assist and protect the less-experienced driver, or when conditions challenge even the best. These include ABS, ESP, ASR traction control, Electronic Brake Distribution, Hill Hold and Brake Steer. The level of intervention varies according to the handling mode selected.

Design: everything for a reason

The McLaren MP4-12C has been designed around a demanding mechanical package that puts emphasis on aerodynamics, compact dimensions, performance and efficiency, practicality and comfort. Although the design of the 12C was driven by aerodynamics, it aims to remain contemporary and elegant throughout its lifetime as well as distinctive among its peers.

Frank Stephenson, McLaren Automotive Design Director, helped finalise the design: “Like most designers it’s a boyhood dream to work with high performance sports cars. They are the purest expression of speed and purpose and, with increased consumer demand in this market and environmental aims to the fore, offer designers the ultimate challenge.

The 12C design was therefore led by aerodynamics. At McLaren we have been able to use the Formula 1 techniques and the huge expertise that the company has amassed at the pinnacle of the sport,” explained Stephenson.

“All the fins, vents and the flat underbody are there for a reason. No styling addenda have been incorporated for appeal or style alone. This aerodynamic purity explains why this car can hit top speed with great stability without resorting to tea tray wings or deep front air dams. I really feel that the styling communicates the 12C’s engineering integrity and technical benefits and it is this purity that makes the design timeless.”

The overall design theme supports engineering aerodynamic ambitions. Purity of lines then give the car its character. Successful car design is based on proportions and McLaren’s styling team, whilst driven by the demands of the purest airflow, honed a mix of concave and convex surfaces that present balanced proportions and a feeling of lightness. Nothing is out of place on the car and surfaces interact smoothly and with purpose; surfaces that are integrated into the whole of the car along two continuous lines that flow round the body.

The front is very low since it does not have to house large engine cooling radiators, two of which are mounted longitudinally at the sides. This offers the added benefit of segment-leading space for storage under the bonnet.

The 12C’s face is dominated by large and distinctive air intakes and bi-xenon headlights with LED running lights inspired by the form of the McLaren logo. The McLaren logo itself also graces the bonnet of a car for the first time.

Illumination from the running lights bleeds into three distinctive gills just above the headlamps. The windscreen is deep and low for superb forward visibility and redolent of the McLaren F1: in wet weather it is swept by a single weight-saving pantograph wiper blade, as was the F1.

Stephenson again: “The 12C does not reproduce the F1 design but it unashamedly builds on its functionally-driven engineering and design highlights such as the large, deep windscreen and the low cowl to give the driver good visibility for accurate placement on the road. Any similarities are there for a reason.”

From the side, the 12C cannot be mistaken for another sports car. The dominant side air inlets act as turning vanes and help direct cooling air over the side radiators. This shape was designed and optimised using McLaren’s extensive computational fluid dynamics capability. Likewise, the scalloped shoulders drive airflow to the airbrake, thereby enhancing its effectiveness in the aerodynamic package.

The other prevailing design characteristics are the dihedral doors (a hereditary gene from the McLaren F1), which has a clear purpose, like every other element of McLaren’s design ethos.

The concept of dihedral doors is simply to allow the driver and passenger to get into and out of the car as easily as possible as well as allowing a smaller door opening than would otherwise be necessary.

The simple act of moving the door forward and upwards invites the driver to step across the sill and sit in the car more easily. In tighter parking situations, dihedral doors allow ingress and egress in a situation where another car has parked too closely. In traditional door systems a huge parking space is necessary to permit the doors to open wide enough.

With its single hinge, the dihedral doors offer weight-saving features and are unique to the McLaren brand. As is the unique handle-free door entry system.

The 12C’s rear is unique. It has an aggressive, business-like appearance with its downforce-optimised rear diffuser. The exhaust pipes exit high and in the centre of the car and the rear end is open to ensure efficient evacuation of hot air from the engine bay. The engine itself is visible through the top deck. The LED tail light clusters do not dominate the rear and are hidden behind horizontal black bars. They are only visible when illuminated: the two upper bars light up as LED brake lights and turn indicators.

Aerodynamic efficiency drove the 12C’s design. High downforce helps maintain traction, cornering ability and stability while low drag aids top speed and acceleration. It has a completely flat underbody and smooth upper body surfaces to yield a highly effective drag coefficient and generate very high levels of balanced downforce at high speed.

A nose splitter gives more downforce at the front while guide vanes near the front and rear wheels help to increase downforce with minimal drag penalty and direct air towards the all-important diffuser at the rear.

The active Airbrake is another innovation that made its debut on the F1 supercar and was also incorporated into the SLR. It deploys hydraulically under braking, or when the driver wants to trim the car for increased downforce by using a switch on the Active Dynamics Panel.

Under braking, a piston operated by transmission hydraulics raises the Airbrake to a certain angle. Once a small amount of wing angle is pushed into the airflow, the centre of aerodynamic pressure forces the bottom of the ‘wing’ back. In this way, it raises the airbrake to maximum angle using the ‘free’ airflow rather than relying on another mechanical device.

The Airbrake moves the centre of pressure of the 12C rearwards, whereas it would normally move forward under braking. It improves yaw stability under braking and allows the brakes to work more effectively due to increased downforce. It is also a weight-saving solution that took almost 50 per cent of weight out of the mechanism.

Overall, the 12C is lower, shorter and narrower than key competitors, but has much shorter front and rear overhangs due to its longer wheelbase – a layout that promotes stability and assists handling response.

Inside: it all starts with the driver

Packaging was fundamental to the McLaren MP4-12C design challenge. Externally, the car had to be compact, yet internally it had to offer an unparalleled driver and passenger environment where comfort and driving enjoyment at all levels were not compromised.

“With the interior, we have created a real step forward in the packaging of a sports car. Moving the driver and passenger closer together improves driving control and moving the pedals improves the problem of wheel well intrusion. We also repackaged many of the major components that normally sit under the dashboard to allow for more space and a unique form. Packaging is one of the 12C’s really strong points,” said Frank Stephenson.

But the creativity of the interior design itself aimed to set new standards. The whole focus is on making the 12C cockpit a uniquely comfortable and functional space. The design offers a symmetry that wraps around the occupants and makes them feel not only physically, but also emotionally comfortable.

The interior is extremely space efficient and is designed to accommodate ?thpercentile adults in comfort. This has been partly achieved by the 7 inch touch screen telematics system oriented in ‘portrait’ mode. This is a first for the automotive industry and is more intuitive than ‘landscape’ orientation – we read down a page and our mobile telephones and other personal information devices are configured this way.

This is one of the many reasons the 12C design is able to buck the trend towards ever wider sporting cars. The innovative information centre provides all normal telematics functions such as audio, navigation and telephony, while providing some new features never before seen in a car. Meridian, the renowned producer of state-of-the-art sound systems, is developing its first ever in-car system for the 12C.

McLaren designers paid great attention to all-round visibility for both safety and driving precision.

The low cowl gives a full six degrees downward vision from eye height and, importantly, allows the driver a clear view of the front of the car. The view of the top of the front wings, with the highest point positioned directly above the centre of the wheel, also facilitates perfect placement of the 12C in a corner. Rear vision is excellent too and an internal buttress with a rear three-quarter glass provides a clear rearward view.

The steering wheel is probably the most important sensory item for any driver. Apart from the feel and feedback from the front wheels, the actual grip and design of the wheel itself is paramount. The steering wheel is ‘clean’ – there are no buttons to distract the driver. It also needs to be small and very tactile.

McLaren designers and engineers found the solution to the steering wheel design challenge under their own roof. Having employed an advanced and compact airbag, the steering wheel design was then inspired by McLaren’s racing expertise.

The steering wheel grip of the 12C is as technically precise as a McLaren racing driver’s wheel.

This is because past Formula 1 championship-winning drivers’ grips were modelled and scanned and the most effective feel and thickness of their wheels was replicated for a high performance road car.

Such attention to detail is to be found throughout the McLaren 12C’s interior and the car does not suffer an over abundance of switches, knobs and dials.

The layout and ergonomics of the interior are aided by the 12C’s packaging. The driver and passenger sit closer together, giving the driver a better feeling of control for placing the car on the road accurately as well as leaving more room between the driver and the door panel. This allows not only more space for arm movements during hard driving, but also provides space for an additional ‘door console’.

Like the McLaren F1, the driver has controls on both sides, which allows for a rational positioning of switches:

• Climate controls on each door console

• Telematics on the upper centre console

• Active Dynamics Panel on the middle centre console

• Transmission and minor controls on the tunnel console

• Trip computer and cruise controls on steering column

As such, all groups of controls have their own place and are accessible within a hand’s distance from the steering wheel. The instrument cluster has a large central tachometer and digital speed readout. Behind the steering wheel (and moving with it) is a Formula 1-inspired rocker for changing gears. It has been engineered to deliver a Formula 1 haptic. The science of haptics has been applied to all the controls in order to generate a consistent and high quality feel. All the controls are bespoke, designed exclusively by McLaren, and not a single one has come from the parts bin of another manufacturer.

The Active Dynamics Panel provides two rotary switches and four push buttons:

• ‘Start/Stop’

• ‘Active’ activates all the dynamic controls.

• ‘Winter’ sets powertrain, suspension and electronic aids to maximum driver support.

• ‘Launch’ initiates the launch control system.

The two rotary switches control ‘powertrain’ and ‘handling’, each having three position settings for normal, sport and high performance driving modes.

• ‘Powertrain’ changes throttle response, gearbox strategy, shift times and impulse (how much one can feel the gearchange). The coaxial ‘Manual’ button controls use of manual gearbox functions.

• ‘Handling’ changes stability control, steering weight, suspension firmness and roll stiffness. The coaxial ‘Aero’ button allows the driver to deploy the airbrake for increased downforce.

The supportive, light weight seat is comfortable and electrically-adjustable for height. There is plenty of stowage space in the car with a shelf behind the seats big enough for small bags and a ‘floating’ centre console that leaves space beneath for a large storage container.

The interior’s simplicity belies a world-class level of comfort and safety features that will include a full quota of airbags, fully automatic dual zone climate control, sophisticated telematics and audio systems, parking sensors, trip computer, cruise control and electric memory seats.

Testing and simulation

McLaren has developed one of the most sophisticated driving simulators in the world. It is an immensely powerful tool that can be used to predict handling, performance, and a multitude of other dynamic properties.

The simulator was initially designed to improve the performance of the Formula 1 cars. But it has also been used intensively in the design and development process for the 12C, where modelling offers the opportunity to test likely outcomes without having to build a component that might turn out to be inadequate. It saves both money and time and it is perhaps the most effective technology transfer from Formula 1 to road cars; the handling and suspension of the McLaren MP4-12C was developed using exactly the same tools and techniques as the McLaren Formula 1 cars.

The crash test requirements are a good example of how simulation helps speed up development. Long before the first Carbon MonoCell had been constructed, the design had been through hundreds of passive crash test simulations. When the time came to submit a real world crash test, the 12C passed with flying colours.

“Outside of McLaren, it is almost unknown to meet our standards out of the box,” said Dick Glover, “but simulation worked out perfectly for us. It is difficult enough to achieve first time success like this with just a relatively predictable, ductile aluminium structure yet McLaren managed first time out with its MonoCell and added aluminium structures. We are very proud of that.”

Simulation didn’t stop at the design stage. Although over 20 prototypes have been built for an exhaustive test programme around the globe, the simulator remains a key tool and a differentiator from most competitors.

Different engineering teams have cars undergoing specialized testing including hot weather in Bahrain in the height of the 2009 summer, cold weather testing in the Arctic, engine development, gearbox calibration, electrical testing and ride, handling and durability programmes.

Before the first prototype was available, the dynamic test team, aided by professional racing driver and McLaren test driver Chris Goodwin, tested early parts on the simulator as well as a development chassis and various engine mules. When dynamic testing started, development and constant refinement of engine, gearbox, tyres, aerodynamics, braking, steering and suspension began in earnest to match all projected values and targets.

The testing programme moved into a more ‘aggressive’ phase following the principles of Formula 1 testing where a car and dozens of people maximise track time during the day and work on improvements overnight. The principle is ‘why test one thing when you can do ten’. Prototypes went to a test track for six weeks with all the experts and suppliers. The car followed a rigorous regime of testing almost 24 hours a day, seven days a week for six weeks. This turbocharged programme accelerated the development time.

Production

The production process for the McLaren MP4-12C will enable McLaren to build on its recent success of record production volumes and quality for a luxury supercar with the SLR.

The McLaren Production System brings a large scale lean production mentality into a small-scale, flexible operation. The process is championed by Production Director, Alan Foster’s experiences at Japanese and European car manufacturers.

“Quality is the most important thing to customers,” said Foster, “and quality management is a fundamental part of building a McLaren. For my team it is an absolute passion. It doesn’t matter whether a customer is spending ten thousand pounds or a million, it is their money and they rightly expect to have pride in their purchase and be satisfied with it. Our goal is to ensure that we exceed customers’ expectations,” he concluded.

12C volumes will remain low, but will require a change of mindset for McLaren’s production line teams as the company moves to higher volumes. But the build process will still focus on craftsmanship, a hand-built philosophy but with a lot of science behind it. Quality gates will ensure that a car cannot leave a work station until everything is completed perfectly.

McLaren will maintain its high standards of final approval before a car can be released.

The build of prototypes has already proven the robustness of this approach because investment in the manufacturing assembly fixtures that will actually be used in production has already prepared the team and shown the build process to be on track. The 12C station cycle times have already been reduced by almost a further 20 per cent through knowledge gained from building the prototypes. In short, the risk has been removed from the production process so that final production quality will be guaranteed.

Aftersales, retail distribution, personalisation

Not only is McLaren establishing a new company, a new production plant, an all-new high performance sports car engineered and developed in house… it is also building a global network of retail distribution partners.

This small number of super operators will deliver the dedication and purposefulness necessary to ensure an ownership experience for the 12C that is as good as the car itself.

Ease of repairability, low-cost of servicing and maintenance, and availability of parts are of paramount importance to this customer relationship and have been key targets since the beginning of the 12C project. McLaren aims to offer segment leading performance here too. The principle being that a high performance sports car should not just be a pleasure to drive, but also to own; a car that is efficient to run and own retains its residual value and ensures its owner becomes a repeat purchaser.

Early planning indicates that 25 per cent of sales will be made in the UK, 25 per cent in the USA and the remainder to the rest of the world, notably Germany and mainland Europe, the Middle East and some Far Eastern countries. Although the McLaren MP4-12C has a comprehensive standard specification, customers for such an exclusive car want to have the ability to specify bespoke items, interiors and special equipment for their own car. McLaren has extensive experience of meeting these needs for McLaren F1 and SLR customers.

For example, the 12C will be available in a broad range of exterior paint colours and interior colours and configurations, while carbon fibre components and lightweight forged wheels will reduce weight yet further.

In summary

Motor racing began the McLaren story, but the latest chapter sees the company take that inspiration and develop it further on the road – and track.

McLaren has a heritage that spans 45 years during which time it has won 163 Grands Prix, 12 F1 World Championship Driver’s titles and eight Constructor’s titles.

McLaren achieved the most dominant season ever in F1 (15 wins out of 16 races in 1988) just as it dominated the Can-Am championship winning five titles in the late 1960s and early 1970s. McLaren has also won three Indianapolis 500 races and the prestigious Le Mans 24 Hours at its first attempt in 1995.

McLaren remains the only manufacturer to win the F1 World Championship, the Indianapolis 500 and Le Mans – the ‘triple crown’ of the motor sport world.

On top of McLaren’s racing record it can lay claim to a road car heritage spanning 20 years, having produced the fastest production road car in history, the McLaren F1. Success does indeed breed success and McLaren intends to continue in this vein.

“McLaren Automotive is well on the way to offering not only an extraordinary new sports car but also to building an innovative new company,” explained Antony Sheriff, McLaren Automotive Managing Director.

“It is an exciting time for all of us at McLaren. We have built a new company, we are constructing a new global dealer network and a purpose-built production plant and, of course we are launching the first pure McLaren car for more than a decade. The best way I can describe the McLaren MP4-12C is to say it is not a ‘but’ car, it is an ‘and’ car:

• It offers class-leading performance and class-leading economy and CO2 emissions

• It has small dimensions and great packaging

• It is well-equipped with high safety standards and is lightweight

• It has dramatic dynamic potential and the ride quality of an executive saloon car

“When we embarked on the 12C project, we set ourselves ambitious targets. After all, building a car that matches the performance of competitors is not good enough for us. With a McLaren badge on the front, it needs to be the best.”

“So we developed everything from scratch because it was the only way we could ensure we met our ambitious goals and did not compromise the car – a new chassis concept, new engine, new gearbox, new suspension system, new telematics system; everything is new. As exciting as it has been for us, we hope the 12C will prove even more exciting for our customers,” Sheriff concluded.

“I am really proud of what the whole McLaren Automotive team has achieved with the 12C,” said Ron Dennis, McLaren Automotive Chairman.

“We respect and admire our competitors in the high performance sports car market, just as we do in the world of Formula 1, but I also believe that fierce competition drives technology and innovation and produces ever better products.

“With the McLaren MP4-12C we are determined to deliver the best car in its sector by almost any measure. It is our philosophy to push what is possible in car design and engineering and bring innovation and engineering excellence to the performance car world. We have an incredibly dedicated team at McLaren who continue to drive this company to ever greater achievements, and the 12C represents the passion within, as the first of this new range of performance cars from McLaren,” he concluded.

Story by McLaren Automotive

In Detail

| submitted by | admin |

| type | Series Production Car |

| built at | Woking, England |

| price $ | $ 229,000 |

| price €/td> | €200,000 |

| price £/td> | £168,500 |

| engine | 90º M838T V8 w/Dry Sump Lubrication |

| position | Mid, Longitudinal |

| aspiration | Twin Turbo |

| block material | Aluminum |

| valvetrain | DOHC, 4 Valves per Cyl w/dual VVT |

| displacement | 3799 cc / 231.83 in³ |

| bore | 93 mm / 3.7 in |

| stroke | 69.9 mm / 2.8 in |

| compression | 8.7:1 |

| power | 447.4 kw / 600 bhp @ 7000 rpm |

| specific output | 157.94 bhp per litre |

| bhp/weight | 418.41 bhp per tonne |

| torque | 600 nm / 442.5 ft lbs @ 3000 rpm |

| redline | 8500 |

| body / frame | Carbon Fiber Monocoque ‘MonoCell’ w/Aluminum Front & Rear Subframes |

| driven wheels | RWD |

| wheel type | Forged Aluminum |

| front tires | 235/35 R19 Pirelli PZero |

| rear tires | 305/30 R20 Pirelli PZero |

| front brakes | Cast Iron Discs |

| rear brakes | Cast Iron Discs |

| front wheels | F 48.3 x 21.6 cm / 19 x 8.5 in |

| rear wheels | R 50.8 x 27.9 cm / 20 x 11 in |

| f suspension | Double Wishbones w/Coil Springs, Active Hydraulic Dampers |

| r suspension | Double Wishbones w/Coil Springs, Active Hydraulic Dampers |

| curb weight | 1434 kg / 3162 lbs |

| weight distro | 42.5 % / 57.5 % |

| wheelbase | 2670 mm / 105.1 in |

| front track | 1656 mm / 65.2 in |

| rear track | 1583 mm / 62.3 in |

| length | 4507 mm / 177.4 in |

| width | 1909 mm / 75.2 in |

| height | 1199 mm / 47.2 in |

| transmission | 7-Speed Seamless Shift |

| tran clutch | Dual-Clutch |

| top speed | ~330 kph / 204.93 mph |

| 0 – 1/4 mile | ~10.9 seconds |

| 0 – 100 kph | ~3.3 seconds |

| 0 – 200 kph | ~9.1 seconds |

| combined fuel econ eu | 11.7 L/100 km or 20.10 mpg-us |

| emission | 279 g/km |