2003 Ford Model U Concept

Building on the heritage started with the Model T, Ford’s Model U concept begins Ford Motor Company’s second century of innovation.

Equipped with an array of upgradable technologies and a multi-function tailgate, Model U can stick with you and adapt to your needs if your life changes.

Powered by the world’s first supercharged hydrogen internal combustion engine, equipped with a hybrid electric transmission and pioneering green materials and processes, Model U is a vision for the future. It is Ford’s model for change – exploring the benefits a vehicle provides to its users, the way it is manufactured and how it impacts the world.

Reconfigurable Designs

The Model U fits Ford’s Outfitters image with its flexible design that can adapt to meet any individual’s needs and perform any type of function. Its design is determined and confident, accentuated by a tough stance and pronounced wheel arches. With seating for up to four people, lots of storage space and built-in flexibility, it provides sensible solutions in an innovative way.

This project was very exciting for us, says Laurens van den Acker, chief designer for the Model U. To embody the spirit of the Model T, we had to design an extremely ingenious car that could grow with your needs and meet an incredible packaging challenge. Model U doesn’t compromise interior space for the occupants or cargo despite the storage space needed for the hydrogen tanks and the hybrid powertrain.

Flexible manufacturing plays a role in allowing easy reconfiguration of a vehicle in the future. Various types of vehicle body architectures can be constructed with common nodes and common extruded tubes joined with low energy-efficient methods. This could also allow many different vehicles to be built in a single assembly plant with reduced inventory and lower tooling cost.

This type of efficiency is also expressed in the interior of the Model U. The armrests on all four doors are exactly the same, as are the center armrests in the front and rear seating rows. This modularity begins to facilitate the recovery of the cradle-to-cradle materials as Model U is dismantled, assuring highest-quality recycling of these valuable substances.

Exterior

Exterior

The Model U’s unique 3-box profile exterior has a tough modular look. Body panels are visually separated through different finishes and are made of different materials. The body side has a glossy appearance; the doors are matte and grooved for both design appearance and structural integrity. The body structure is aluminum; the front side panels are built with a natural fiber-filled composite material.

Its flexibility makes it capable of performing rugged jobs as well as driving to an evening out. It provides different driving experiences with one vehicle. Model U goes from completely closed to completely open. When completely open, it looks like a pickup. The rear seats can be removed to provide a longer loading floor.

The roof of the Model U is a power-retractable canvas soft top that opens rearward to offer a nearly open-air motoring experience. The rear of the vehicle also can be opened with power controls. The rear window folds into the deck lid and the deck lid then folds back and down into the floor so that it is hidden and safe from being damaged.

The Model U also features a power hood that opens from the windshield toward the front of the SUV. The hinges are hidden in the front bumper.

Interior

The interior of the Model U is uncluttered and open, but allows for flexibility through the use of the innovative slot system. It is shown as an affordable base vehicle that grows with a customer’s life and aspirations. The Model U ties back to the Model T roots in that it is classless and allows people to be aspire to something more, yet it delivers for the people who can already afford more.

An important feature of Model U is the ‘layering’ of major design elements. This is done to visually and physically separate the materials from each other, a vital aspect when designing for disassembly.

There are three basic layers that make up the interior:

-The bottom surface is the base of the vehicle. It is painted a dark gray and helps to emphasize the glossier layer. Much of the hydrogen fueling system, including its four tanks, is beneath this surface. -The middle layer is the floor, which has a semi-gloss appearance. Nicknamed ‘the magic carpet’ by the designers, it flows from the top of the instrument panel, down the footwell over the hydrogen storage tanks and all the way to the tailgate. Through it run the main three slots. -The top layer is fabric and is used on all points of contact, including the seats, armrests, steering wheel and dash. The fabric is an orange color that is fresh and modern, adding visual warmth to the Model U.

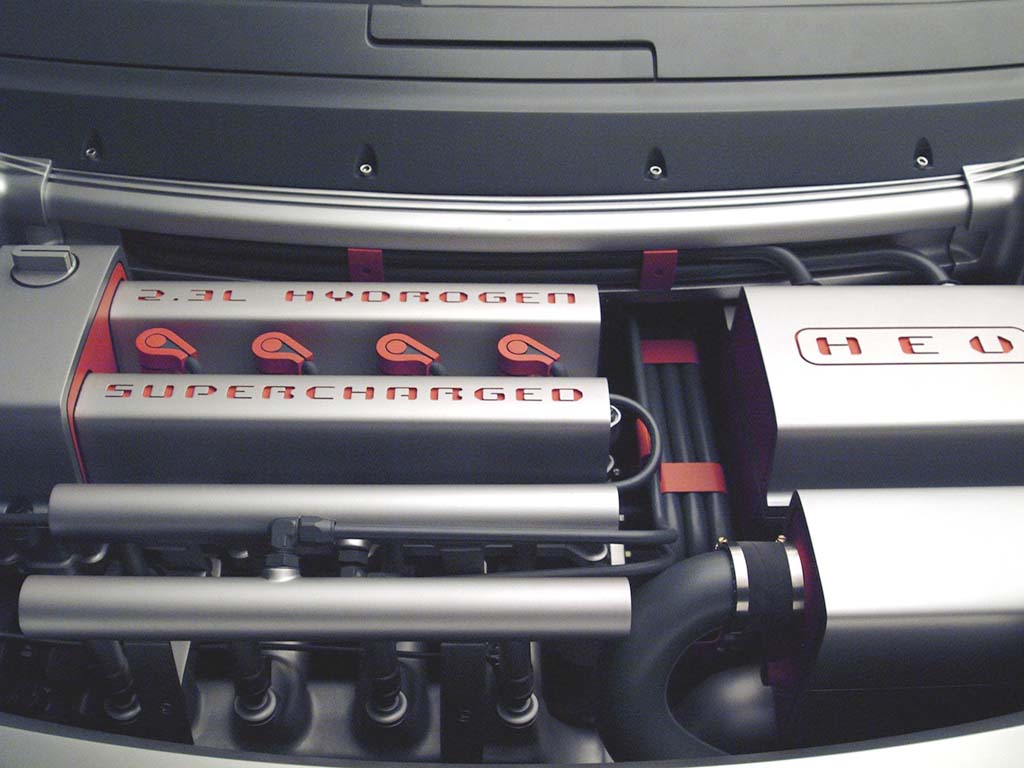

Hydrogen Internal-Combustion Engine

Model U is powered by internal combustion engine (ICE) that is optimized to run on hydrogen. The engine is supercharged and intercooled for maximum efficiency, power and range. Its emission of all pollutants, including carbon dioxide, is nearly zero, and the engine is up to 25 percent more fuel-efficient than gasoline engines. A hybrid-electric transmission system further improves efficiency.

The hydrogen ICE is a common-sense powerplant that uses existing, proven technologies to deliver the environmental benefits of a hydrogen fuel cell – but at a fraction of the complexity and cost.

The hydrogen ICE is based on Ford’s global 2.3-liter I-4 engine used in the Ford Ranger, the European Ford Mondeo and a number of Mazda vehicles. The engine is optimized to burn hydrogen with 12.2:1 high-compression pistons, fuel injectors designed to handle hydrogen gas, a coil-on-plug ignition system, an electronic throttle and new engine management software.

Because hydrogen has a very wide combustion range (from 4 to 75 percent), hydrogen-fueled engines are able to use a wider range of air/fuel mixtures than gasoline engines, and can be run in the fuel-efficient lean regime without the complications of pre-ignition or knock. Much like a diesel engine, the hydrogen ICE runs unthrottled while under way, with air/fuel mixtures as lean as 86:1 during highway cruise, compared to the 14.7:1 of gasoline-powered vehicles. It can reach an overall efficiency of 38 percent, which is approximately 25 percent better than a gasoline engine.

Because there are no carbon atoms in the fuel, combustion of hydrogen produces no hydrocarbon or carbon-dioxide emissions. Even without aftertreatment, oxides of nitrogen (NOX) are very low, and catalyst research may soon reduce tailpipe output of potentially smog-forming emission to below ambient conditions in many cities.

Designing a gasoline engine to burn hydrogen fuel has typically resulted in significantly lower power output – until now. Ford researchers have shown that with supercharging, the hydrogen ICE can deliver the same power as its gasoline counterpart and still provide near-zero-emissions performance and high fuel economy. The centrifugal-type supercharger provides nearly 15 pounds per square inch (psi) of boost on demand.

Also, Model U uses a novel dual-stage intercooling process. After leaving the supercharger, the intake air passes through a conventional air-to-air intercooler, then through an air conditioning-to-air intercooler for a further reduction in temperature. This patent-pending solution further improves the performance of the engine.

Ford Modular Hybrid Transmission System

The hydrogen ICE is joined with an advanced hybrid electric transmission technology called the Ford Modular Hybrid Transmission System (MHTS). The torque converter from a conventional transmission is replaced with a high-voltage electric motor and two hydraulic clutches that permit the motor to operate independently of, or in concert with, the engine.

The electric motor simultaneously fills the role of flywheel, starter, alternator and hybrid traction motor.

The hybrid system is known as a parallel arrangement, which means that Model U can operate on either the hydrogen ICE engine or electric motor, or both for extra power. A regenerative braking function reclaims energy that would otherwise be lost as heat, storing it in the 300-volt, air-cooled battery pack for the next acceleration, passing maneuver or hill climb.

When the driver comes to rest at a traffic light, the engine can automatically be switched off to save fuel. When the accelerator is applied, the electric motor instantly starts the engine, the clutch to the transmission engages, and the vehicle begins to pull away, all within 300 milliseconds.

MHTS provides significant increased fuel efficiency while delivering familiar performance and drive characteristics. The technology is designed with minimal effect on the base transmission so as to reduce complexity and cost compared to other hybrid systems.

Fuel Storage

Model U can carry up to 7 kilograms of hydrogen on board. Its fuel tanks, made of a 3-millimeter aluminum pressure barrier with a carbon-fiber structural casing, are rated to an operating pressure of more than 10,000 psi.

Hydrogen offers the potential for a sustainable, cleaner burning fuel. Ford Motor Company, in conjunction with BP, is exploring the potential for hydrogen production. BP currently produces hydrogen from natural gas, in an efficient, effective manner. Continued support from industry and government, through FreedomCAR and other efforts, might one day make its use a reality in vehicles like Model U.

Conclusion

The Model U is a realistic approach to the future, guided by a powerful, positive vision. It follows the traditions of the Model T by being designed for the masses and addressing social issues, specifically environmental concerns. The Model U represents how using and producing personal transportation can have a positive effect on the planet instead of simply minimizing negative effects.

Story by Ford Motor Company, edit by Supercars.net

In Detail

| submitted by | Richard Owen |

| engine | Hydrogen ICE Inline-4 |

| aspiration | Supercharger w/Intercooler |

| power | 112.6 kw / 151 bhp @ 4500 rpm |

| torque | 208.8 nm / 154 ft lbs @ 4000 rpm |

| f brake size | mm / in |

| r brake size | mm / in |

| wheelbase | 2685 mm / 105.7 in |

| front track | 1583 mm / 62.3 in |

| rear track | 1583 mm / 62.3 in |

| length | 4230 mm / 166.5 in |

| width | 1810 mm / 71.3 in |

| height | 1651 mm / 65.0 in |

| gear ratios | :1 |