2003 Ford Focus RS WRC

A radical new look hints at the most technically advanced and revolutionary Ford Focus world rally car, unveiled today prior to its competition debut on the Rally New Zealand on April 11. Ford Rallye Sport has unveiled the most technically advanced and revolutionary rally car ever with the launch of the Ford Focus RS WRC 03 at the team’s Dovenby Hall base in Cumbria, England.

Innovative in its radical styling, the evolution version of the successful Focus RS, winner of 11 world rallies since its debut in 1999, will make its competition debut on the fourth round of the FIA World Rally Championship, the Rally New Zealand, on 10-13 April.

The new Focus RS is radically different in both looks and mechanics to the car which competed on the opening three rounds of the 2003 championship.

Technical director Christian Loriaux and his engineering team at M-Sport, the company which operates Ford’s world rally programme, have added significant performance improvements to the most dependable and reliable car in the championship and a stunning new aerodynamic package gives the Focus RS an eye-catching contemporary look.

Highlights of the new Focus RS include:

-Radical changes to styling and aerodynamic packages -New rear suspension system -Improved weight distribution -Weight savings throughout the car -New body shell and a roll cage which far exceeds minimum FIA safety requirement -New lightweight engine developed and built by Cosworth Racing -Revised wiring loom and electronic control system -More efficient engine and transmission cooling -Enhanced Digital Messaging System -Revised hydraulic control system

The car is Loriaux’s first design since joining the team at the start of 2002. Starting with a clean sheet of paper, initial design work began in mid-May 2002 and just seven months elapsed between then and the car’s first brief test run six days before Christmas.

Since then the car has undergone a comprehensive testing programme, most of it on gravel, in advance of its New Zealand debut.

Engineers at M-Sport and Fords newly announced Team RS technical department in Cologne, Germany, worked closely on the project.

Mainstream engineers at Ford undertook detailed analysis on Loriaux’s roll cage design and the new rear suspension while the climatic wind tunnel in Cologne was used for advanced testing in the development of the cooling system and aerodynamics.

Interview with technical director Christian Loriaux

Ford Rallye Sport’s technical director, Christian Loriaux, is the man behind the new Ford Focus RS WRC 03. Here he reveals what is new on the car, the thinking behind its design and tells the story of the transformation from drawings to our world championship contender.

If World Rally Cars can be described as stunning, then that is the word I would use to describe the new Ford Focus RS WRC. The large rear wing and revised bumpers give the car a very contemporary look from the outside and much has changed underneath as well, but it remains clearly recognisable as a Focus. We began with a clean sheet of paper and we’ve ended with a radical, revolutionary rally car which retains all that was good from the previous model. That has been taken forward to a higher level and blended with much that is new and the end result is a car that we know is faster and believe will be just as reliable as its predecessor.

Aerodynamics

Aerodynamics is one of the key areas of development and, by the very look of the vehicle, the most strikingly obvious. We wanted to improve the downforce on the Focus as we’ve been losing time to our key rivals on the faster rallies like Finland and it’s one area where we have to make gains. I’ve had quite a lot of experience in aerodynamics and know how important a strong package is in gaining vital seconds on faster rallies. There was clearly room for improvement over the 2002 car. One look tells you there have been some quite radical changes. There is a new, larger rear wing, the front bumper has been redesigned while the cooling scoops and all the body panels are new. That was a big task. We needed a lead time of four months to manufacture the body panels. We carried out a lot of preparation work in Ford’s wind tunnel and spent three days testing different ideas before finally settling on the basic package. When I arrived at Ford Rallye Sport in January 2002 the aerodynamic work for last year’s car was almost finished, so I had little input on that. We knew we needed to make changes but, as aerodynamic alterations are strictly restricted by homologation, this is our first opportunity.

Suspension

The front suspension remains similar to that used on the 2002 model, although there are some changes to the dampers, which once again includes weight saving. The regulations limit what we can do to the suspension, and we’ve already put in a lot of work in that area last season, but we have incorporated small geometry improvements. I think we’ve probably reached the point where we have optimised the front suspension as far as the regulations will allow us to go. As for the rear suspension, there are some major changes. We have completely redesigned that area to improve road handling by using the dynamics of the suspension and saving weight. This was a big job and, technically, a risk, but I’m glad we made the decision to do it. The work we’ve done there is not really something I want to go into in any great depth. All I really can say is that it’s very different to what we had before.

Weight

Another of our target areas was weight. We wanted to save weight and, just as importantly, distribute the weight to those areas of the car where we want it to improve balance and handling. We initially reviewed everything and examined the possibilities of reducing the weight on every area of the Focus, from the engine through to the dampers. As a team, I think we succeeded in doing that. Pi Research designed a new wiring loom and electronic control system which saved a lot and Cosworth Racing also made a significant saving with the new engine. The car is now right on the weight limit. We could easily go quite a lot below that so that has allowed us to add weight and reinforce parts in certain areas to achieve the weight distribution we want.

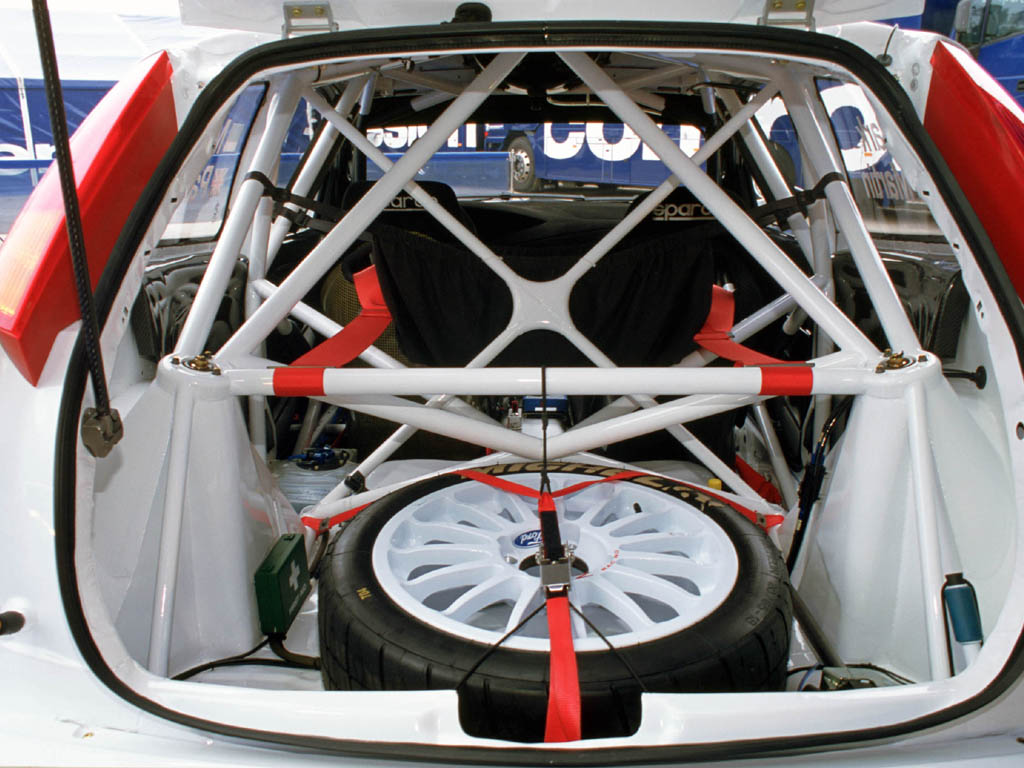

Body shell and roll cage

Both the body shell and roll cage are totally new. The cage has been designed to far exceed the minimum FIA safety requirements. It’s one area of the car where we’ve actually increased the weight to improve driver safety. The Focus already had a good reputation in this area but we took the decision that if we could make the car even safer for our drivers, then we should do so. The main area of danger in a rally car is from side impact accidents and we’ve tried to position the driver and co-driver as far inboard as possible by making the transmission tunnel narrower. The cage is further outboard of the cockpit and we’ve redesigned the side impact bars to improve crash protection there. We all know that rallying can be a dangerous sport and we have a responsibility to our drivers to make the cockpit area of the car as safe as we possibly can.

Engine

Cosworth Racing, which has built the engines for the Focus at Northampton since 2000, has built a new two-litre Duratec ‘R’ engine. There is a significant weight reduction over the 2002 engine, making this the lightest rally engine the company has built, and revisions to the turbocharger have helped produce better response and more top end power. We’ve also redesigned the cooling package to improve efficiency and we should see cooler running temperatures on the hot rallies like the Acropolis and Cyprus. It is interesting to note that since 2000 Cosworth has made a 25% reduction in engine weight and generated an 8% increase in engine performance.

Transmission

We wanted to keep the transmission similar to that in the 2002 car. This car has a two-year lifespan and developing a new transmission is a hugely expensive job, especially when we will have a new car for 2005. As a result of the changes to the suspension, we have a new propshaft and driveshafts and there will be a new transfer box introduced later in the season. That should be ready for Germany. Otherwise the transmission shows very few differences, although we have optimised the internal parts to save weight.

2003 Ford Focus RS WRC Gallery

In Detail

| submitted by | Richard Owen |

| built at | Detroit, Michigan, USA |

| engine | Cosworth Inline-4 |

| position | Front Transverse |

| aspiration | Twin Garett Turbocharged |

| valvetrain | 4 Valves per Cyl |

| displacement | 1991 cc / 121.5 in³ |

| bore | 84.8 mm / 3.34 in |

| stroke | 88 mm / 3.46 in |

| power | 223.7 kw / 300 bhp @ 6500 rpm |

| specific output | 150.68 bhp per litre |

| bhp/weight | 243.9 bhp per tonne |

| torque | 550 nm / 405.7 ft lbs @ 4000 rpm |

| body / frame | Unit Steel |

| driven wheels | Front Engine / 4WD |

| front brakes | Brembro Vented Discs w/8-Pot Calipers |

| f brake size | x 370 mm / x 14.6 in |

| rear brakes | Brembro Vented Discs w/8-Pot Calipers |

| r brake size | x 370 mm / x 14.6 in |

| front wheels | F 45.7 x 20.3 cm / 18.0 x 8.0 in |

| rear wheels | R 45.7 x 20.3 cm / 18.0 x 8.0 in |

| steering | Rack & Pinion w/Power Assist |

| f suspension | MacPherson Struts w/Reiger Adjustable Dampers, Anti Roll Bar |

| r suspension | MacPherson Struts w/Reiger Adjustable Dampers, Anti Roll Bar |

| curb weight | 1230 kg / 2712 lbs |

| wheelbase | 2615 mm / 103.0 in |

| length | 4152 mm / 163.5 in |

| width | 1770 mm / 69.7 in |

| height | 1380 mm / 54.3 in |

| transmission | Xtrac 240 6-Speed Sequential |

| gear ratios | :1 |

Story by Ford Motor Corporation