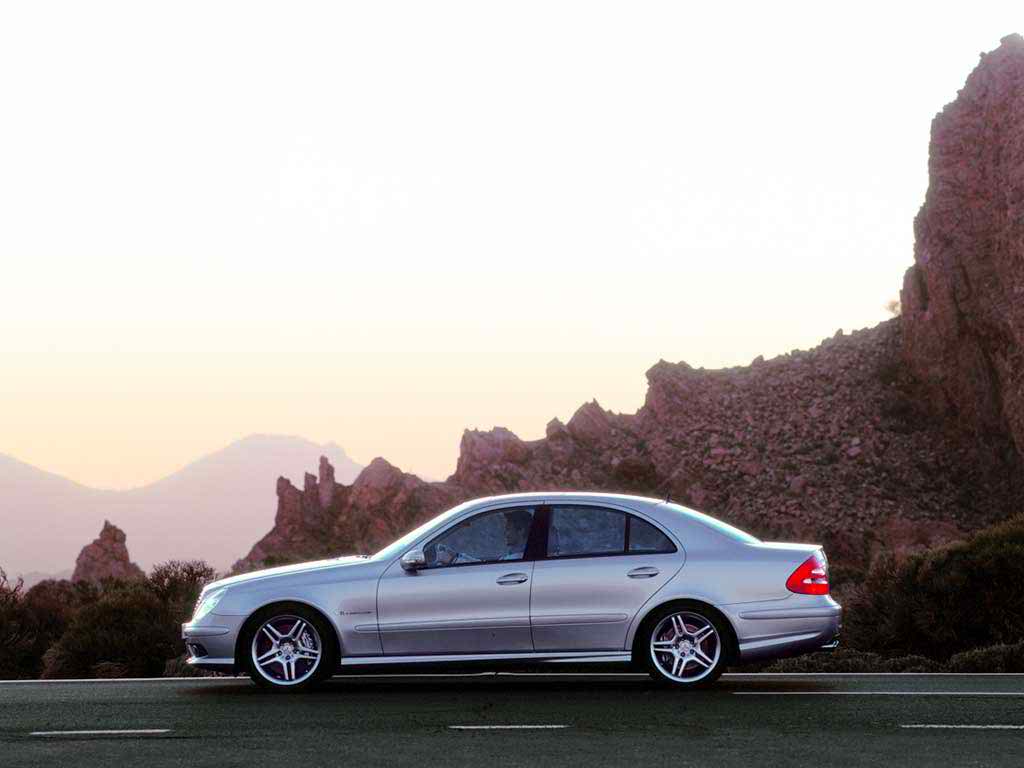

2002 Mercedes-Benz E 55 AMG

The new E 55 AMG represents the latest chapter in the illustrious history of supercharged Mercedes-Benz cars. This is an era that began in the late 1920s with the legendary supercharged Mercedes-Benz S to SSKL models.

With the latest E 55 AMG, Mercedes-AMG has created a worthy successor to the popular outgoing model. Some 12,000 units have rolled off the production line between 1997 and 2001. This makes the E 55 AMG the most successful AMG model in the company’s 35-year history.

In breif the new E 55 offers an AMG supercharged V8 engine with 5.5-l displacement, F1-style steering-wheelmounted gearshift buttons, AIRMATIC DC air suspension tuned to AMG specifications and a full complement of equipment including AMG 18-inch twin-spoke wheels, AMG bodystyling and nappa/nubuk leather upholstery.

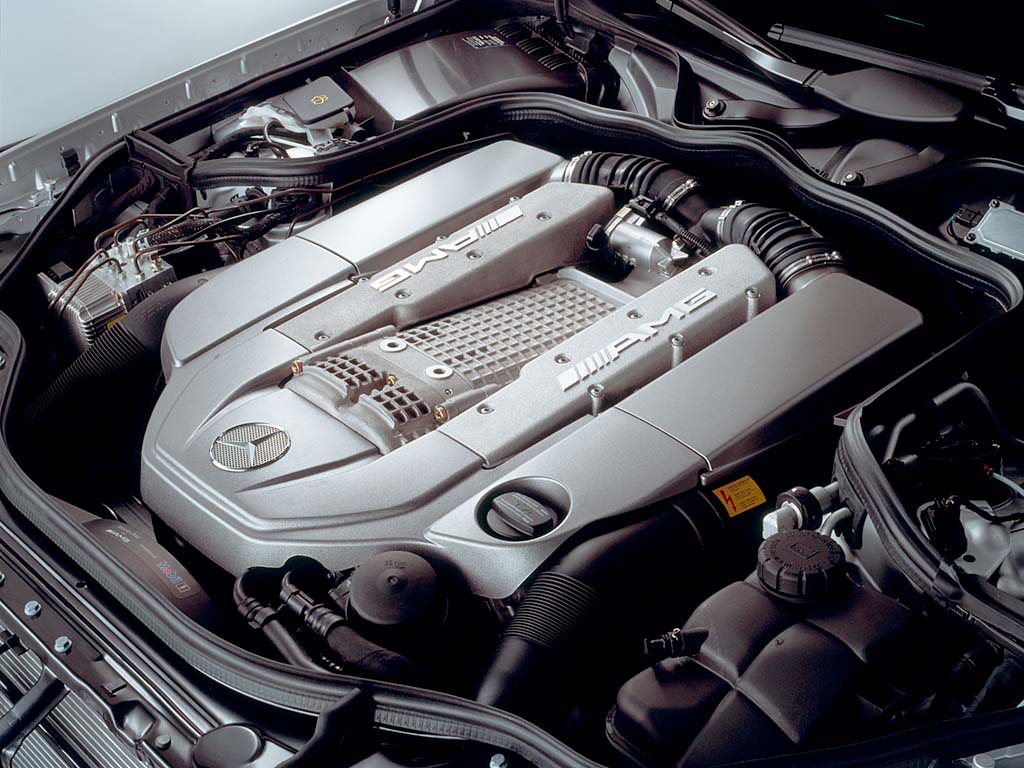

The high-performance 5.5-litre V8 from the SL 55 AMG develops 350 kW/476 hp at 6100 rpm and maximum torque of 700 Nm in the new E 55 AMG. These figures are rooted in the torque of the supercharged V8. The engine delivers 560 nm of torque to the crankshaft as low down as 1500 rpms, and this grows to 650 Nm only 500 rpm later. The peak torque of 700 Nm is available anywhere between 2650 and 4500 rpm. The supercharged V8 thus develops 34 percent more power and 32 percent more torque than the outgoing model with its naturally aspirated eight-cylinder engine.

The scroll compressor is not permanently running and is only activated at a certain engine speed and load condition. The engine electronics send the command to an electro-magnetic coupling, which immediately switches on the compressor by means of a separate poly-V-belt. The system has two advantages: on the one hand, it means that the compressor can be activated in a split-second and the driver’s acceleration command implemented directly and without delay, and on the other, the engine consumes less fuel in part-throttle operation when the compressor is not in use.

Integrated into the compact charger module is the engine-mounted intercooler, which works according to the extremely effective principle of an air/water heat exchanger. The air compacted by the compressor is channelled along to a water source, which flows in a separate circuit from the engine coolant. In this way, the air can be cooled before it enters the eight combustion chambers.

The wealth of experience built up by Mercedes-AMG engineers in motorsport and the construction and development of high-performance engines came in useful with the supercharged V8 engine which powers the E 55 AMG. Specifically, the following components were specially constructed:

-the crankcase has been reinforced with special stiffening ribs and side bolts. -the crankshaft is precision balanced. Modified bearings and a more resistant material have been used to take into account the high torque of the super-charged engine. The stroke has been extended from 84 to 92 millimetres. -the pistons are made of a special, extremely temperature and pressure resis-tant material and enjoy the benefit of oil injection cooling. -the oil supply, with sump, catch tray and more efficient pump, was subjected to thorough modifications. -the cylinder heads, of which the inlet and outlet ducts have been optimised to take into account the increased air mass flow. -the camshafts have extended valve opening times, which improves the fuel supply to the combustion chambers. -the valve train has a twin spring assembly, which allows the rated engine speed to be increased from 5600 to 6100 rpm -the engine electronics take on additional tasks in the AMG engine, such as the logic-controlled activation of the compressor.

The valuable experience gained over 35 years at the sharp end of car racing was a key component in the development of a power transmission system which features a larger cardan shaft, new steel rear axle with reinforced wheel location elements and drive shafts, and spring links made from a highly robust welded steel structure. The rear axle differential has cooling fins to lower the oil temperature by as much as 20 degrees Celsius.

The E 55 AMG is equipped with an AMG SPEEDSHIFT five-speed automatic transmission, which adapts itself to driving styles. AMG SPEEDSHIFT features the familiar Touchshift system, which allows manual gearshift, if desired. The driver uses the selector level to change gear in the M driving mode, whilst in S (Standard) the automatic transmission takes full charge. The C (Comfort) mode, where the transmission shifts up through the gears earlier and back down later, enhances a more relaxed driving style.

In order to ensure that the engine power at their disposal is transferred to the road with maximum effectiveness, the Mercedes-AMG engineers have redesigned the chassis and braking system. The AIRMATIC DC semi-active air suspension system with ADS II allows the driver to select a more relaxed or extremely dynamic setting for their journey. The damping and springs use state-of-the-art micro-electronics to adapt instantaneously to the driving situation in hand. To this end, data is processed relating to the steering and yaw angle of the body, longitudinal and transverse acceleration, vehicle level and driving style. The desired suspension setting can also be selected manually through three stages, thus satisfying the most diverse customer preferences.

The renowned performance of the pioneering SL 55 AMG braking system with Sensotronic Brake Control (SBC) is also given the opportunity to impress in the E 55 AMG. The high-strength, internally ventilated and perforated brake discs, which measure 360 x 36 millimetres at the front axle and 330 x 26 mm at the rear, deliver notable deceleration .

Story by DaimlerChrysler

In Detail

| submitted by | Richard Owen |

| engine | V8 |

| position | Front Longitudinal |

| aspiration | Supercharged and Intercooled |

| valvetrain | SOHC, 3 Valves per Cyl |

| displacement | 5439 cc / 331.9 in³ |

| bore | 97 mm / 3.82 in |

| stroke | 92 mm / 3.62 in |

| compression | 9.0:1 |

| power | 355.0 kw / 476 bhp @ 6100 rpm |

| specific output | 87.52 bhp per litre |

| bhp/weight | 259.4 bhp per tonne |

| torque | 700 nm / 516.3 ft lbs @ 2650-4500 rpm |

| redline | 6500 |

| body / frame | Unit Steel |

| driven wheels | RWD |

| front tires | 245/40 ZR 18 |

| rear tires | 265/35 ZR 18 |

| front brakes | Internally Vented Discs w/ABS, Power Assist, SBC, ESP |

| f brake size | x 360 mm / x 14.2 in |

| rear brakes | Internally Vented Discs w/ABS, Power Assist, SBC, ESP |

| r brake size | x 330 mm / x 13.0 in |

| front wheels | F 45.7 x 20.3 cm / 18.0 x 8.0 in |

| rear wheels | R 45.7 x 22.9 cm / 18.0 x 9.0 in |

| steering | Steeing w/Speed Senitive Power Asisst |

| f suspension | Four-Link, Multi-Link w/Active Air Suspension Unit |

| r suspension | Multi-Link w/Active Air Suspension Unit |

| curb weight | 1835 kg / 4045 lbs |

| wheelbase | 2854 mm / 112.4 in |

| front track | 1583 mm / 62.3 in |

| rear track | 1551 mm / 61.1 in |

| length | 4849 mm / 190.9 in |

| width | 1822 mm / 71.7 in |

| height | 1295 mm / 51.0 in |

| transmission | 5-Speed Auto w/SpeedShift |

| gear ratios | 3.59:1, 2.19:1, 1.41:1, 1.00:1, 0.83:1, :1 |

| top speed | ~250 kph / 155.3 mph |

| 0 – 60 mph | ~4.6 seconds |